- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- ICS TRIPLEX(三重冗余)

- EPRO(爱普诺)

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

real-time update

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

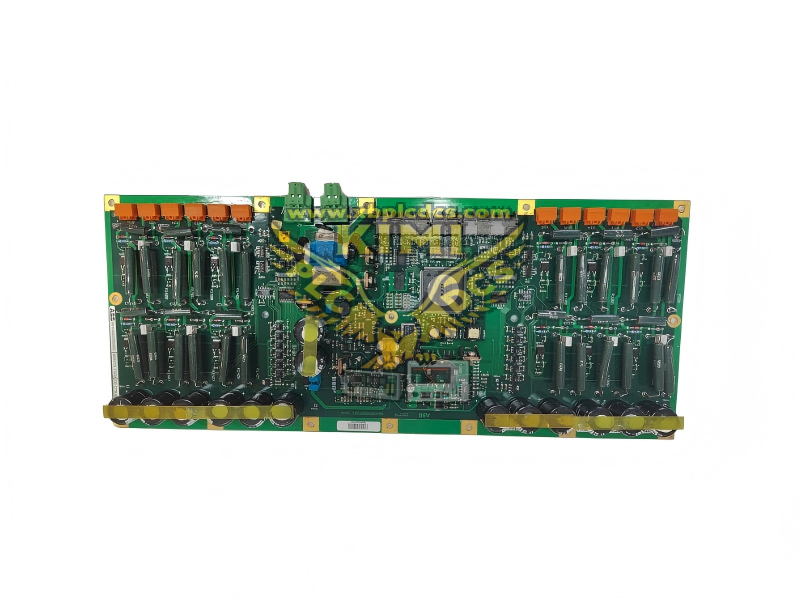

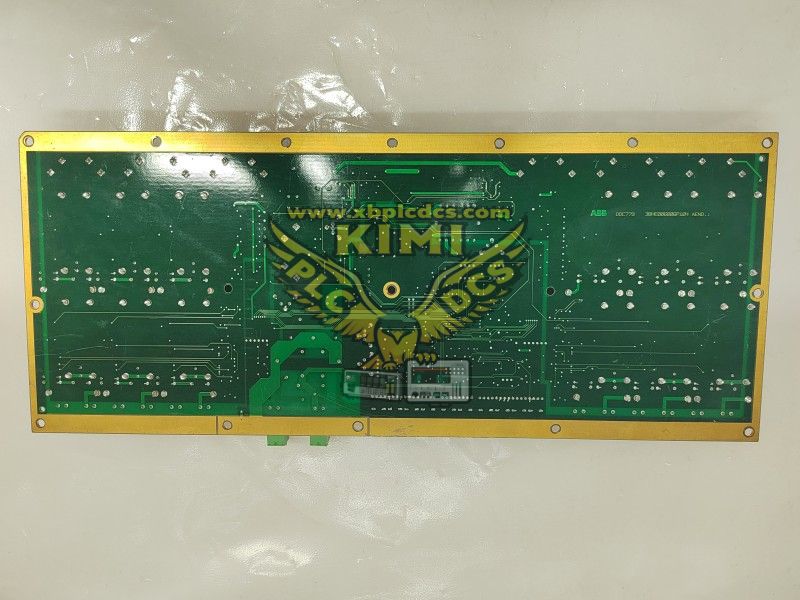

The ABB DDC779BE02 (3BHE006805R0002) is a high - performance dual - channel Profibus DP redundant communication module, which is a key component of ABB's industrial automation and distributed control system (DCS) architecture. It is specially designed to provide reliable, redundant data transmission for critical industrial networks, supporting logically independent dual Profibus DP buses, and providing 12 Profibus DP electrical interfaces and 12 155 Mbps fiber - optic interfaces to meet the needs of redundant dual - network and fiber ring - network topology applications. It supports all preset communication rates in the Profibus DP standard, which can be set through DIP switches or rate - adaptive mode, with a fiber - optic communication distance of more than 20 km, ensuring long - distance and stable transmission of burst data. It has a wide - range redundant dual - power supply of 12-36 V DC with reverse connection protection, 5 dual - color LED status indicators, 4000 V lightning protection for electrical interfaces, 1.5 A over - current protection and 600 W surge protection, and complies with EMC test certification. With a working temperature range of - 40°C to +85°C, IP30 protection grade, and industrial - grade aluminum alloy casing, it is very suitable for harsh industrial environments such as power generation, petrochemical, oil & gas, and manufacturing, where high - reliability communication is crucial for ensuring the continuous operation of the system and reducing downtime.

• Certifications: CE, RoHS, EMC (IEC 61000 - 6 - 2/6 - 4), Profibus DP compliance

• Wide Temperature Range: - 40°C to +85°C operation is suitable for extreme industrial environments such as deserts and cold regions

• Water Treatment: Sewage treatment plant distributed I/O network; water supply system SCADA communication; desalination plant control bus expansion

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.