- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

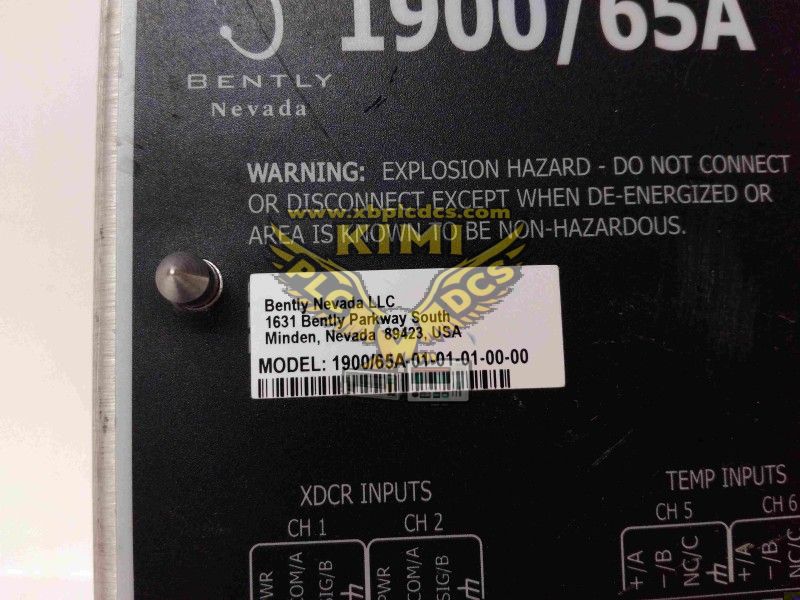

- Part number:BENTLY 1900/65A-01-01-01-00-00

- Product Origin:America

- HS CODE:8708299000

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

Bently Nevada 1900/65A-01-01-01-00-00 Vibration Monitoring Module

Product Description

The Bently Nevada 1900/65A-01-01-01-00-00 is a high-precision vibration and position monitoring module, part of the Bently Nevada 1900 Series System 65 monitoring platform, engineered specifically for critical rotating machinery protection in power generation, oil & gas, petrochemical, and heavy industrial applications. Built with rugged industrial-grade components, advanced signal conditioning, and galvanic isolation, this module delivers exceptional accuracy and reliability in harsh operating environments (extreme vibration, wide temperature ranges, electrical noise) typical of turbine, compressor, pump, and motor installations. Its compact, rack-mount design integrates seamlessly with Bently Nevada 1900 Series chassis, while hot-swappable functionality enables maintenance without disrupting critical machinery protection systems. The 1900/65A-01-01-01-00-00 provides real-time vibration and position monitoring with built-in alarm and trip logic, making it a core component for preventing catastrophic machinery failures and ensuring operational reliability.

Key Functions

The primary function of the Bently Nevada 1900/65A-01-01-01-00-00 module is to monitor vibration, displacement, and position parameters of critical rotating machinery (turbines, compressors, pumps, generators) by processing signals from Bently Nevada proximity probes, velocity sensors, and accelerometers. It features 4 independent monitoring channels optimized for vibration measurement (0-50 mm/s RMS or 0-200 μm peak-to-peak) and shaft position monitoring, with high-resolution signal conditioning and 16-bit analog-to-digital conversion for precise measurement. The module includes configurable alarm and trip setpoints (Alert 1, Alert 2, Danger/Trip) with latching and non-latching logic to trigger protective actions (alarms, shutdowns) when machinery parameters exceed safe operating limits. It incorporates galvanic isolation (channel-to-channel and system-to-ground) to eliminate ground loops and ensure signal integrity in noisy industrial environments, along with surge and ESD protection to withstand harsh electrical conditions. The module provides comprehensive built-in diagnostics to detect sensor faults (open circuits, short circuits), signal loss, and module malfunctions, with LED status indicators for quick visual fault identification and diagnostic data communicated to Bently Nevada's System 65 operator interface or DCS systems via Modbus/4-20 mA outputs. Additionally, it supports calibration and configuration via front-panel controls or software tools, ensuring easy setup and maintenance.

Application Scenarios

The Bently Nevada 1900/65A-01-01-01-00-00 vibration monitoring module is primarily deployed in critical machinery protection systems across power generation, oil & gas, petrochemical, and heavy industrial sectors. In thermal and nuclear power plants, it monitors turbine shaft vibration, generator rotor displacement, and boiler feed pump vibration to prevent catastrophic failures and ensure continuous power generation. For oil & gas production and refining facilities, it monitors centrifugal compressor vibration (pipeline compression stations), gas turbine vibration (wellhead power generation), and pump vibration (crude oil transfer systems) in hazardous Zone 1/2 environments, complying with ATEX/IECEx standards for explosive atmospheres. In petrochemical and chemical plants, it protects critical rotating equipment (reactors, mixers, refrigeration compressors) by monitoring bearing vibration and shaft position, preventing unplanned downtime and ensuring process safety. The module is also essential for marine applications (shipboard main propulsion turbines, auxiliary generators), steel manufacturing (rolling mill motors, blast furnace blowers), and pulp & paper mills (paper machine rolls, pump systems), where it provides reliable machinery protection in harsh operating conditions and enables predictive maintenance by tracking vibration trends over time.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Type | Bently Nevada 1900 Series System 65 Vibration/Position Monitoring Module |

| Number of Channels | 4 Independent Monitoring Channels |

| Measured Parameters | Vibration (0-50 mm/s RMS, 0-200 μm peak-to-peak), Shaft Displacement/Position |

| Input Compatibility | Bently Nevada Proximity Probes (3300 Series), Accelerometers, Velocity Sensors |

| Accuracy | ±0.1% of Reading (Vibration); ±0.5 μm (Shaft Position) |

| Resolution | 16-Bit Analog-to-Digital Conversion (ADC) |

| Isolation Rating | 2500 V AC (Channel-to-Channel); 1500 V AC (System-to-Ground) |

| Alarm/Trip Logic | Configurable Alert 1/Alert 2/Danger (Trip) Setpoints; Latching/Non-Latching |

| Outputs | 4-20 mA (Per Channel), Modbus RTU, Relay Outputs (Alarm/Trip) |

| Protection Features | Surge Protection (6 kV ESD), Short-Circuit Protection, Reverse Polarity Protection |

| Power Supply | 24 V DC (18-32 V DC) or 120/240 V AC; Max Power Consumption: 10 W |

| Operating Temperature | -20°C to +65°C (-4°F to +149°F) |

| Certifications | ATEX, IECEx, CE, UL/cUL Approved |