- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- ICS TRIPLEX(三重冗余)

- EPRO(爱普诺)

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

real-time update

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

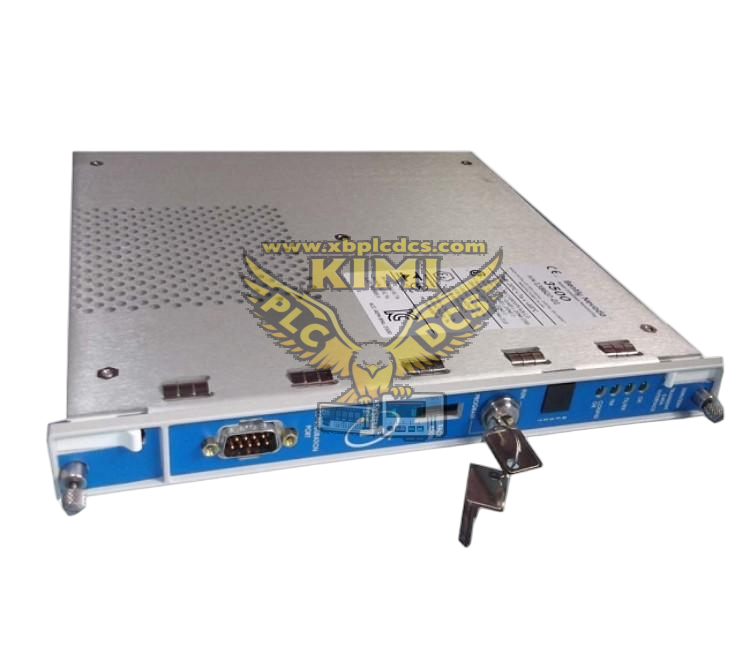

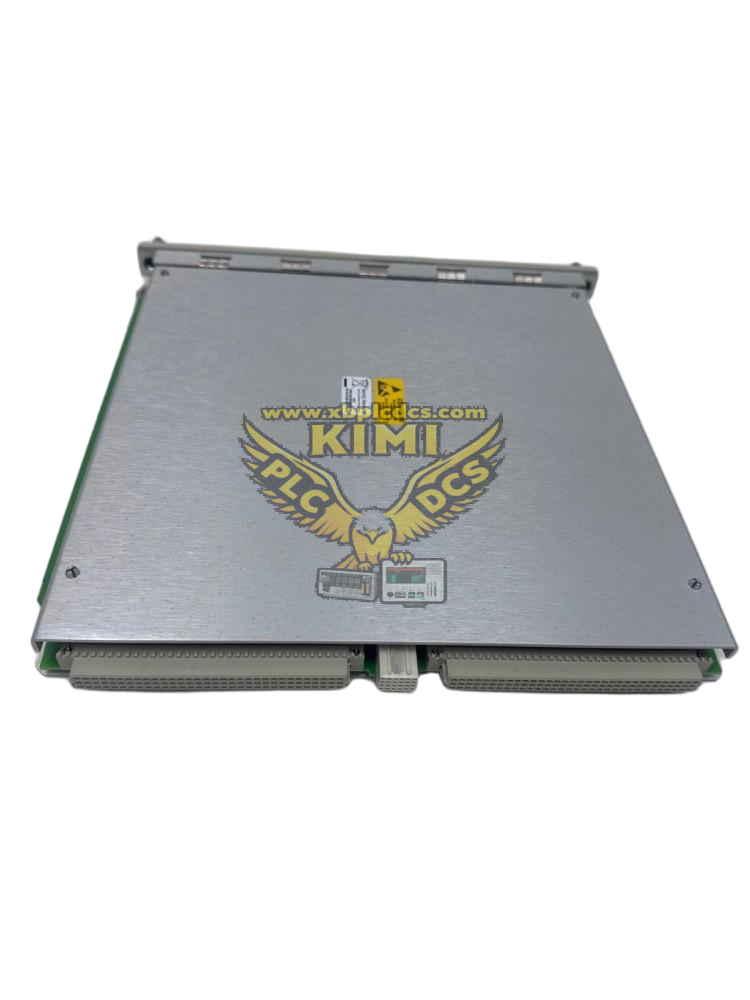

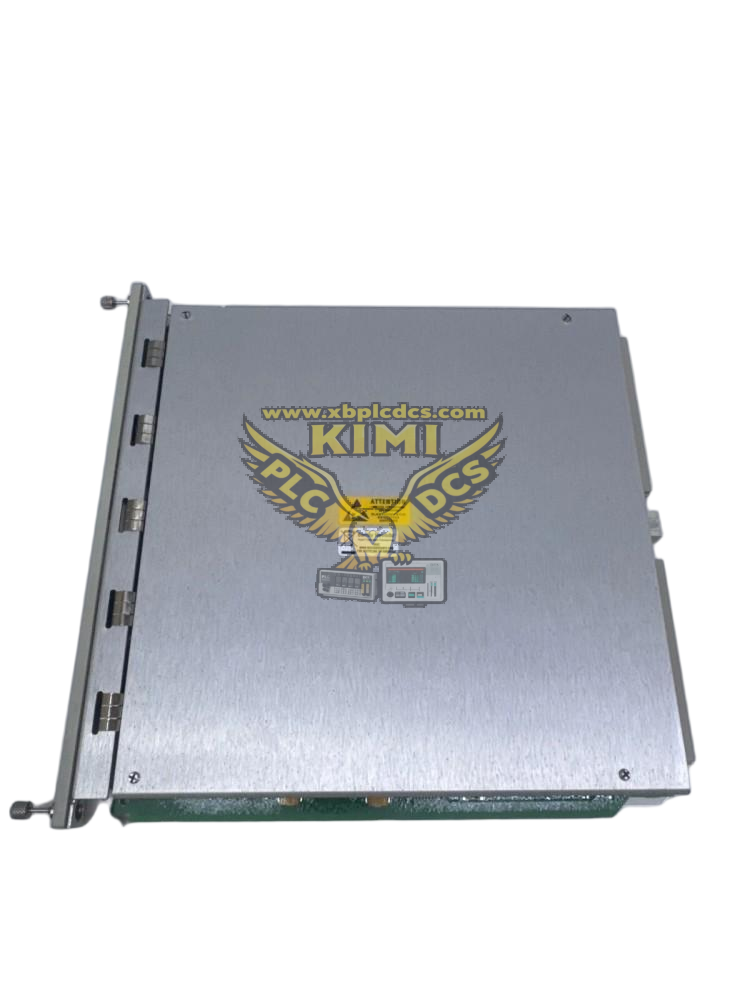

- Part number:3500/22M 138607-01

- Product Origin:America

- HS CODE:8537109021

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

The Bently Nevada 3500/22M 138607-01 is a Standard Transient Data Interface (TDI) Module that serves as the critical communication and data acquisition link between the Bently Nevada 3500 machinery protection system and compatible software (System 1 Condition Monitoring & Diagnostic Software, 3500 System Configuration Software). It integrates the functions of a 3500/20 Rack Interface Module (RIM) with transient data capture capability, supporting both static (steady-state) and dynamic (transient/waveform) data acquisition, event-triggered data logging (pre/post-alarm), and real-time data transmission via USB and Ethernet (copper/fiber) interfaces. As a full-height module for the 3500 rack, it enables engineers to perform advanced fault diagnosis, predictive maintenance, and system configuration for turbines, compressors, pumps, and other rotating machinery in power generation, oil & gas, petrochemical, and heavy manufacturing industries, ensuring reliable operation and minimizing unplanned downtime.

• Certifications: CE, CSA/NRTL/C (Class 1, Div 2), ATEX/IECEx (Zone 2)

• Industrial-Grade Design: Operates in Harsh Temperature & Vibration Conditions

• Mining: Crusher/Conveyor Event-Triggered Data Capture for Unplanned Downtime Prevention.

• Testing: Verify USB/Ethernet Communication & Pre/Post-Alarm Data Capture.

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.