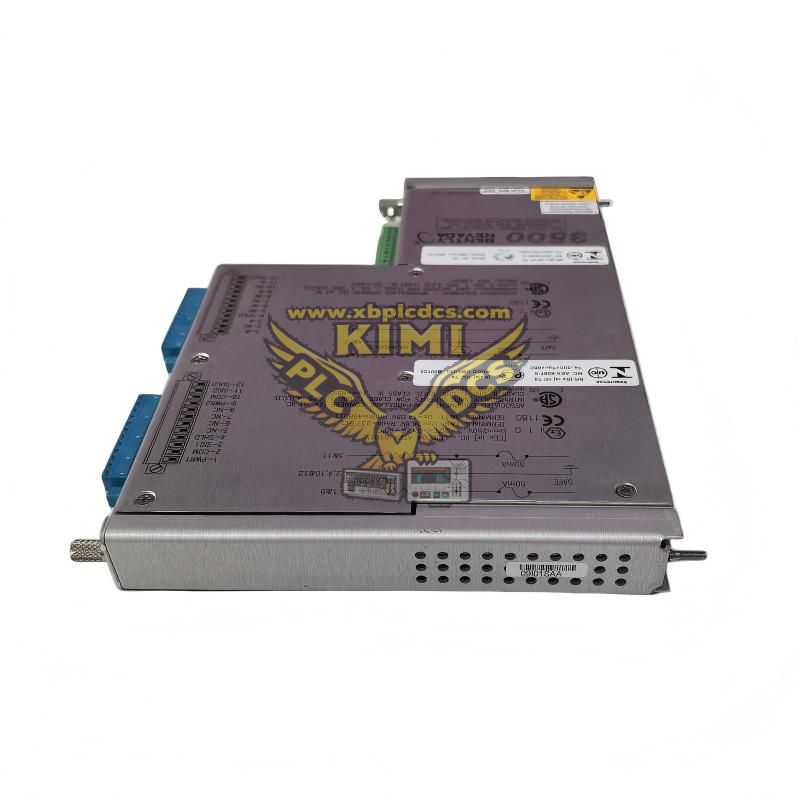

Bently Nevada 3500/42M 135489-02 Proximitor/Seismic Monitor

4‑Channel Module with Internal Barriers (2×Prox/Accel + 2×Velomitor) for 3500 Machinery Protection System

1. Core Product Overview

The Bently Nevada 3500/42M (135489-02) is a 4‑channel Proximitor/seismic monitor module for the 3500 machinery protection system, featuring internal intrinsic safety (IS) barriers and internal terminations, configured with 2×Prox/Accel and 2×Velomitor channels for comprehensive rotating equipment monitoring. It continuously processes input from proximity probes (displacement/radial vibration/eccentricity) and seismic sensors (velocity/acceleration) to generate real‑time static values, compare them against user‑defined alarm/danger setpoints, and trigger relay outputs for machinery protection and personnel safety. The module integrates internal safety barriers with 1000V AC channel isolation, enabling safe operation in hazardous areas (Class I, Div 2) and seamless integration with DCS/PLC via Modbus RTU for data acquisition and control联锁. Built for industrial reliability, it operates in -25°C~+70°C environments with robust EMC immunity and vibration resistance, making it ideal for turbines, compressors, generators, and pumps in power generation, petrochemical, and oil & gas industries.

• Core Role: Machinery vibration/displacement monitoring; alarm/danger threshold comparison; relay interlock output; IS sensor interface; hazardous area safety protection

• Model Info: 3500/42M (model designation); 135489-02 (Bently Nevada part number); 4‑channel Proximitor/seismic monitor; internal barriers (2×Prox/Accel + 2×Velomitor)

• Key Specs: 4 channels (2×Prox/Accel, 2×Velomitor); internal IS barriers; 1000V AC channel isolation; -10V~+10V input; 24V DC power; -25°C~+70°C operating temp; Class I, Div 2 compliant

• Reliability: IEC 61000‑4 EMC; IEC 60068 vibration/shock; internal safety barriers; redundant power; 3500 system fault‑tolerant design

2. Channel Configuration & Sensing Capability

The 3500/42M 135489-02 is configured with 2×Prox/Accel (channels 1–2) and 2×Velomitor (channels 3–4) channels, supporting proximity probe (displacement, radial vibration, differential expansion, eccentricity) and seismic sensor (velocity, acceleration) input for comprehensive machine health monitoring. Each channel conditions the input signal to generate static values (peak‑to‑peak, RMS, DC gap, velocity, acceleration), with configurable alert/danger setpoints for active parameters and danger setpoints for two parameters per channel. Channels are programmed in pairs, allowing up to two monitoring functions simultaneously (e.g., displacement + velocity on a single shaft). The module provides a 4–20mA output per channel for trend analysis and integration with SCADA systems, and supports relay outputs (2×alert, 2×danger) for alarm annunciation and machine shutdown control. The Prox/Accel channels accept -10V~+10V input (max 5mA current), while Velomitor channels process velocity signals for vibration monitoring, ensuring accurate and reliable data for predictive maintenance and machinery protection.

• Channel Setup: 2×Prox/Accel (CH1–2); 2×Velomitor (CH3–4); paired programming; dual function capability; proximity/seismic input compatibility

• Monitoring Functions: Displacement/radial vibration; differential expansion; eccentricity; shaft position; velocity/acceleration; static value generation

• Setpoints & Alarms: Alert/danger thresholds; configurable per parameter; 2×danger setpoints per channel; relay activation; shutdown interlock

• Output Signals: 4–20mA per channel; relay outputs (alert/danger); Modbus RTU communication; DCS/PLC integration; trend analysis data

3. Safety Barriers & Electrical Isolation

The 3500/42M 135489-02 integrates internal intrinsic safety (IS) barriers, providing safe interface with IS sensors in hazardous areas (Class I, Div 2, Groups A–D) without external safety equipment. Each channel features 1000V AC isolation from other channels and the backplane, preventing ground loops and cross‑channel interference for reliable signal processing. The internal barriers limit energy to the sensor circuit, ensuring compliance with IEC 60079-11 for intrinsic safety and reducing the risk of ignition in explosive atmospheres. The module also includes reverse polarity protection, overvoltage (30V DC cutoff) and overcurrent (per‑channel limiting) protection to prevent damage from wiring errors or sensor faults. Electrical isolation between the power input and sensor circuits (2.5kV galvanic isolation) minimizes electromagnetic interference, and LED indicators for power, channel status, and alarms enable quick fault diagnosis for on‑site troubleshooting.

• Intrinsic Safety: Internal IS barriers; Class I, Div 2 compliance; IEC 60079‑11; energy limitation; explosive atmosphere safety

• Electrical Isolation: 1000V AC channel isolation; 2.5kV power/signal isolation; ground loop prevention; cross‑channel interference rejection; EMC immunity

• Protection Features: Reverse polarity protection; 30V DC overvoltage cutoff; per‑channel overcurrent limiting; short‑circuit protection; fault isolation

• Status Indicators: Power LED; channel active LED; alert/danger LED; fault LED; quick troubleshooting; on‑site diagnostics

4. System Integration & Industrial Adaptation

The 3500/42M 135489-02 seamlessly integrates with the Bently Nevada 3500 system, including 3500/20 rack interface modules (RIM), 3500/22 transient data interface (TDI), and System 1 condition monitoring software for centralized data management and analysis. It uses internal terminations for simplified wiring and installation in control cabinets, with compatibility for 3300 series proximity probes, Velomitor seismic sensors, and acceleration transducers. The module operates on 24V DC power from the 3500 system power supply (typical 7.7W consumption) and supports Modbus RTU for communication with DCS/PLC systems, enabling remote monitoring and control. Designed for harsh industrial environments, it withstands -25°C~+70°C temperatures, 5–95% non‑condensing humidity, and vibration (5–50Hz, IEC 60068-2-6) and shock (15g, IEC 60068-2-27) for reliable operation in power generation, petrochemical, and oil & gas applications. The internal barrier design eliminates the need for external safety equipment, reducing installation costs and cabinet space while ensuring compliance with global safety standards.

• 3500 System Compatibility: 3500/20 RIM; 3500/22 TDI; System 1 software; 3300 series sensors; Velomitor/Accelerometer input

• Communication Protocols: Modbus RTU; DCS/PLC integration; SCADA connectivity; remote monitoring; data logging; trend analysis

• Power & Wiring: 24V DC system power; 7.7W typical consumption; internal terminations; simplified wiring; cabinet space optimization

• Environmental Ratings: -25°C~+70°C operating temp; 5–95% non‑condensing humidity; vibration/shock resistance; IP20 protection; industrial durability

5. Typical Applications & Compliance

Key Industrial Sectors: Power generation (turbines/generators); petrochemical (compressors/pumps); oil & gas (pipeline pumps/compressors); paper & pulp (rotating machinery); mining ( crushers/grinders); metal processing (rolling mills).

Core Use Cases: Rotating machinery protection; vibration/displacement monitoring; predictive maintenance; hazardous area safety; alarm/shutdown interlock; DCS/PLC integration.

Certifications & Compliance: IEC 61010‑1 (electrical safety); IEC 60079‑11 (intrinsic safety); IEC 61000‑4 (EMC); IEC 60068 (vibration/shock); Class I, Div 2; CE/UL/RoHS certified.

Quality & Warranty: Bently Nevada genuine module; factory‑tested; 24‑month standard warranty; technical support for 3500 system configuration, channel programming, and safety barrier integration.

YMGK Purchase Information

This section covers key details customers care about regarding purchasing, to support your global industrial product procurement needs.

One-Stop Global Industrial Product Procurement

Sales Manager: KI MI

WeChat: 18059884790

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.

For additional inquiries, reach out to us at any time.

All product names, trademarks, brands, and logos on this site belong to their respective owners. Their use here is for identification only, and does not imply affiliation with or authorization from the rights holders

Technical Documentation | Bently Nevada 3500/42M 135489-02 | 4‑Channel Proximitor/Seismic Monitor with Internal Barriers