- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- ICS TRIPLEX(三重冗余)

- EPRO(爱普诺)

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

real-time update

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

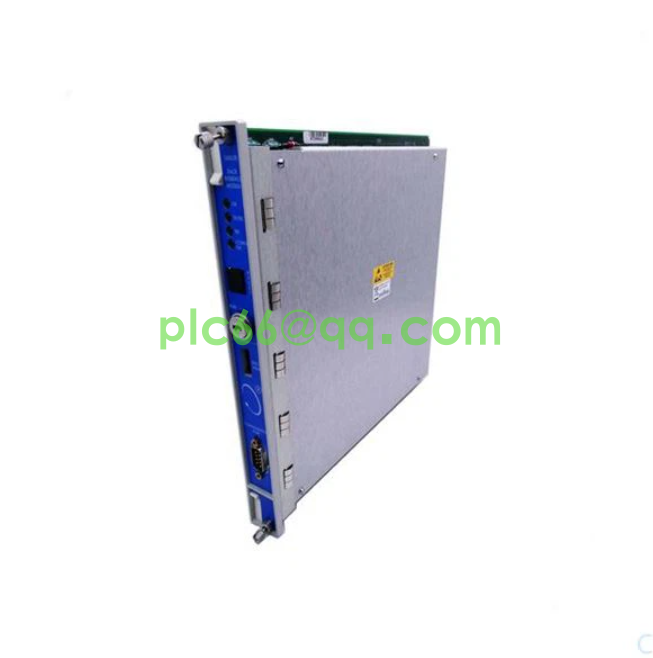

Bently Nevada 3500/50M Tachometer Module

Product Number:Bently Nevada 3500/50M Tachometer Module

Product Overview

The 3500/50M Tachometer Module is a 2-channel module that accepts input from proximity probes or magnetic pickups to determine shaft rotative speed, rotor acceleration, or rotor direction. The module compares these measurements against user-programmable alarm setpoints and generates alarms when the setpoints are violated.The Tachometer Module is programmed using the 3500 Rack Configuration software. The following configuration options are available: l Speed Monitoring, Setpoint Alarming and Speed Band Alarming l Speed Monitoring, Setpoint Alarming and Zero Speed Notification l Speed Monitoring, Setpoint Alarming and Rotor Acceleration Alarming l Speed Monitoring, Setpoint Alarming and Reverse Rotation Notification141538 Rev. PThe 3500/50M Tachometer Module can be configured to supply conditioned Keyphasor signals to the backplane of the 3500 rack for use by other monitors. Therefore, you don't need a separate Keyphasor module in the rack

bently nevada 3500/50M-01-00(288062-02,133442-01) Bently rotational speed module, receives signals from eddy current sensors or magnetic sensors It can be used for speed monitoring of large and medium-sized rotating machinery such as steam turbines, compressors, fans, water pumps, coal mills, gearboxes and motors, and is widely applied in many industries including steel, power, metallurgy, chemical engineering and petrochemicals.

bently nevada 3500/50M-01-00-01(288062-02,133442-01) Bently speed module, a product of Bently Nevada, USA, is specialized in monitoring mechanical vibration and mechanical protection. The bently nevada 3500 Bentley module is used for vibration monitoring of large and medium-sized rotating machinery such as steam turbines, compressors, fans, water pumps, coal mills, gearboxes, and motors. It is widely applied in many industries including steel, power, metallurgy, chemical engineering, and petrochemicals.

The bently nevada 3500 module is a product of Bently Nevada, USA, specializing in monitoring mechanical vibration and mechanical protection.

bently nevada 3500/40-01-00(176449-01,125680-01) Bently displacement module

bently nevada 3500/42-01-00(176449-02,128229-01, 138708-01) Bently Vibration module

bently nevada 3500/45-01-00(176449-04,135137-01) Bently expansion module

bently nevada 3500/50-01-00-01(288062-02,133442-01) Bently Rotational speed module

bently nevada 3500/42-01-00(176449-02,128229-01, 138708-01) Bently Vibration module

Tachometer module 3500/50-AXX-BXX-CXX option description

A: I/O module

0 1 I/O module with internal terminals

0 2 I/O module with external terminals

0 3 TMR I/O module with external terminals

0 4 I/O module with internal safety barriers and internal terminals

B: Approval agency options 0 0 None 0 1 CSA/NRTL/C

C: Monitor usage

01 Speed measurement 02 Reverse rotation

133388-02 3500/50 Tachometer module

133442-01 I/O module with Internal terminals

136703-01 I/O module with internal terminals and discrete internal safety barriers

133434-01 I/O Module with External terminals

133450-01 TMR I/O module with external terminals

bently nevada 3500/50-01-00-01(288062-02,133442-01) The Bently speed module receives signals from the Bently eddy current sensor

The Bently Nevada 3500/50M Tachometer Module is a crucial component within the Bently Nevada 3500 Series Machinery Protection System. Its primary function is to accurately and continuously monitor the rotational speed of machinery.

What the 3500/50M Does

The 3500/50M module is designed to:

Measure Rotational Speed: It takes input signals from proximity probes or magnetic pickups pointed at a shaft or gear, converting these into a precise indication of the machine's rotational speed (typically in Revolutions Per Minute - RPM).Provide Speed Alarms: Users can configure multiple speed setpoints to trigger alarms (Alert and Danger) within the 3500 system. These alarms can then activate relays (via a 3500/32M Relay Module) to alert operators or initiate automated actions.Support Speed-Related Measurements: Beyond just current speed, the 3500/50M can also provide data for related measurements such as:Rotor Acceleration: Rate of change of speed.Reverse Rotation: Detection of the shaft spinning in the wrong direction.Zero Speed: Confirmation that the machine has stopped.Generate Buffered Outputs: It provides buffered "raw" speed signals that can be sent to external diagnostic equipment, such as a Bently Nevada ADRE® system, for more in-depth analysis.Enhanced Capabilities ("M" version): The "M" in 3500/50M signifies an enhanced or newer version compared to its predecessors. This typically means improved signal processing, potentially wider measurement ranges, better diagnostics, and compliance with the latest industry standards like API 670 for machinery protection systems. It also features more robust internal diagnostics and can provide more detailed information to the system's data acquisition software.

Why Speed Monitoring is Important

Accurate speed monitoring is fundamental for the safe and efficient operation of rotating machinery:

Operational Control: Many machines operate within specific speed ranges for optimal performance.Protection Against Underspeed/Overspeed: While dedicated overspeed modules (like the 3500/54M) handle critical trip functions, the 3500/50M provides general speed monitoring and alarming for both low and high-speed conditions that are not catastrophic but require attention.Process Interlocks: Speed information can be used in control logic to enable or disable other process functions.Performance Monitoring: Tracking speed trends can help in understanding machine degradation or efficiency changes.

System Integration and Configuration

The 3500/50M operates seamlessly within the Bently Nevada 3500 Series rack:

Half-Height Module: It occupies a single half-height slot in the 3500 rack.Channel Capacity: Each module typically provides two speed input channels.I/O Module Options: Similar to other 3500 modules, it uses separate I/O modules for transducer connections. These can include internal or external termination options.Communication: The module communicates with the 3500 Rack Interface Module (RIM) and ultimately to external software (like System 1*) for configuration, data display, and alarm logging.

Typical Applications

The Bently Nevada 3500/50M Tachometer Module is widely applied across industries for continuous speed monitoring of various rotating machines:

Pumps: Monitoring operating speed to ensure flow rates and prevent cavitation.Fans and Blowers: Tracking fan speed for air flow control and preventing resonant conditions.Motors: Monitoring motor RPM for efficiency and load management.Compressors: Observing speed during startup, shutdown, and load changes.Gears and Shafts: Any application where precise rotational speed measurement is required for operational control or condition monitoring.Generators: Monitoring generator speed for synchronization and power quality.

The 3500/50M provides reliable and accurate speed data, enabling operators and maintenance personnel to proactively manage machine health and ensure safe, efficient operation.

This article is originally written by KIMI Xiaoming. Please bring the link www.xbplcdcs.com when reprinting

Client Concern

Part Number : Bently Nevada 3500/50M Tachometer Module

Manufacture : Bently Nevada

Origin : USA

Condition : Brand New with 12 month warranty

Lead Time : in stock

Status: 100% original

Payment method: T/T. Currencies for receipt: US dollar, New Zealand dollar, Chinese yuan, euro, Hong Kong dollar, Australian dollar, British pound, Canadian dollar, ruble and other global currencies

Sales Manager: Li Ming

WeChat: 18059884790

WHATSAPP:+86 18059884790

Click to add 【WHATSAPP】 and start a new experience of instant communication

Email:plc66@qq.com

Bently Nevada 3500/50M Tachometer Module Not what you want?

For more product information about Bently Nevada, please click on (YMGK)

BENTLY Hot Module

| 1900/25 Vibration Monitor | 177230 Seismic Transmitter | 3500/82 Stator Insulation Monitoring System |

| 1900/65A General PurposeEquipment Monitor | 3500/64M Dynamic Pressure Monitor | 3500/65 channel Temperature Monitor |

| 3500/42M Proximitor seismic Monitor | 3500/70M Recip lmpulse Velocity Monitor | 3500/62 Process Variable Monitor |

| 3500/44M Aeroderivitive cT vibrationMonitor | 3500/72M Recip Rod Position Monitor | 3500/60 and 3500/61TemperatureModules |

| 3500/46M Hydro Monitor | 3500/77M Recip cylinder PressureMonitor | 3500/45 Position Monitor |

| 3500/15 AC and DC Power Supplies | 3500/94M VGA Display Monitor | 3500/33 16-Channel Relay Module |

| 3500/15 AC and DC Power Supplies | 9100D Portable Shaker Vibra on Calibrator | 3500/25 Enhanced Keyphasor Module |

| 3500/22M Transient Data Interface Module | 3500/92 Communication Gateway | 3500/06 Weatherproof Housing |

| 3500/32M 4-channel Relay Module | 3500/91EcD Communication catewayModule | 3500/05 system Rack |

| 3500/40M Proximitor Monitor | 3500/50M Tachometer Module | ADAPT 3701/40MachineryDynamics Monitor |

| ADRE Sxp and 408 DSPi | TK3 Proximity System Test Kit | Bently Nevada 3500/53 Electronic overspeed detection system |

Welcome to browse other products in our store and learn what else we can offer!

For models not listed, please contact us!

Don't worry if you can't find the model you want on our website!

Send your inquiries to plc66@qq.com, or click here: Contact Us.

We are well aware that meeting your specific needs is of vital importance.

Our professional team will respond to your inquiry promptly within 24 hours.

Please rest assured that we can provide most of the original parts you need.

At YMGK, customer satisfaction is our top priority. Welcome to contact us at any time.

We will do our best to find the perfect solution that meets your industrial needs for you. Your success is our success

Why choose YMGK

1. Inventory: A large amount of stock available and a variety of discontinued spare parts.

2. Affordable price: Competitive price.

3. Speed: Quick response and efficient delivery.

4. Professionalism: Solid business organization.

5. Internationalization: Global partner network and preferred suppliers

For more product videos, please click to view

The main reasons for choosing Bently Nevada are as follows:

The main reasons for choosing Bently Nevada are as follows:

High reliability and stability: Bentley Nevada's systems are renowned for their high reliability and stability, capable of operating normally under harsh environmental conditions and suitable for a wide range of industrial applications. This reliability ensures the continuity and stability of the factory's production process, reducing production interruptions and losses caused by system failures.

Comprehensive monitoring and protection functions: The company's system offers comprehensive monitoring and protection functions, such as vibration monitoring, temperature monitoring, shaft displacement monitoring, etc., capable of real-time monitoring of the operating status and health condition of the equipment. These functions help to detect equipment abnormalities in a timely manner and take corresponding preventive or repair measures, thereby ensuring the safe operation of the equipment and extending its service life.

Excellent flexibility and scalability: Bentley Nevada's systems feature a variety of interfaces and protocols, enabling communication and control with a wide range of different types of devices and systems, meeting the factory's requirements for equipment integration and communication. Meanwhile, the system is easy to expand and upgrade, and can adapt to the changes in the production scale of the factory and the introduction of new technologies.

Convenient operation and easy maintenance: Its system features a user-friendly interface, which is easy to use and maintain, reducing operational difficulty and training costs. In addition, the system also provides a wealth of diagnostic and maintenance tools to help users quickly locate and solve system problems.

Rich product line and professional experience: As a brand under the Power Systems Group of General Electric (GE) or Baker Hughes, it has a diverse product line, including 3300/3500 monitoring and protection systems, System 1 equipment management and diagnostic platforms, etc. These products and technologies have been successfully applied in multiple industries, demonstrating Bentley Nevada's professional strength and rich experience in industrial automation and process control.

Enhancing production efficiency and safety: By using Bentley Nevada's system, factories can achieve real-time monitoring and early warning of equipment, reduce equipment failure rates, and improve operational efficiency. Meanwhile, the system provides accurate fault diagnosis and maintenance suggestions, enabling the factory to respond quickly and efficiently and reducing safety risks in the production process.