- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

real-time update

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

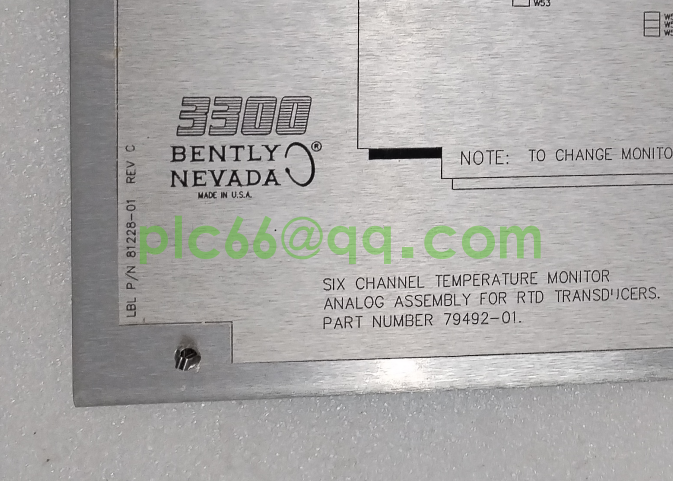

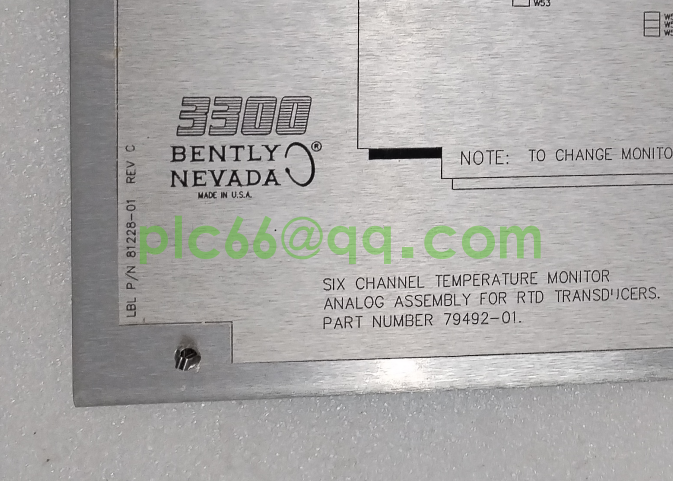

- Part number:3300/35 79492-01

- Product Origin:America

- HS CODE:8479909090

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

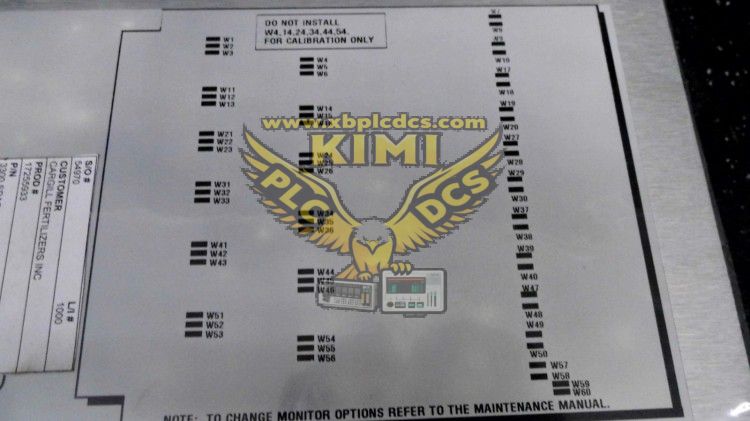

The Bently Nevada 3300/35 79492-01 is a six-channel resistance temperature detector (RTD) monitor, a key component of the 3300 Series machinery protection system, designed for real-time online temperature monitoring of rotating machinery critical parts (e.g., bearings, windings, gearboxes, lubrication systems). It accepts inputs from up to six 4-wire RTD sensors (Pt100 standard), features independent channel configuration, high-precision measurement, and configurable alarm thresholds (alert, danger) for early fault warning. Compatible with 3300 Series standard racks, it supports hot-swappable replacement and seamless integration with 3300 system monitors, widely used in power generation, oil & gas, petrochemical, and heavy manufacturing for machinery over-temperature protection and predictive maintenance.

• Certifications: CE, CSA/NRTL/C (Class 1, Div 2), ATEX/IECEx (Zone 2)

• Configurability: Via 3300 System Configuration Software (Range, Alarms, Outputs)

• Mining: Crusher/Conveyor Gearbox & Bearing Temperature Early Fault Warning