PLC/DCS module

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

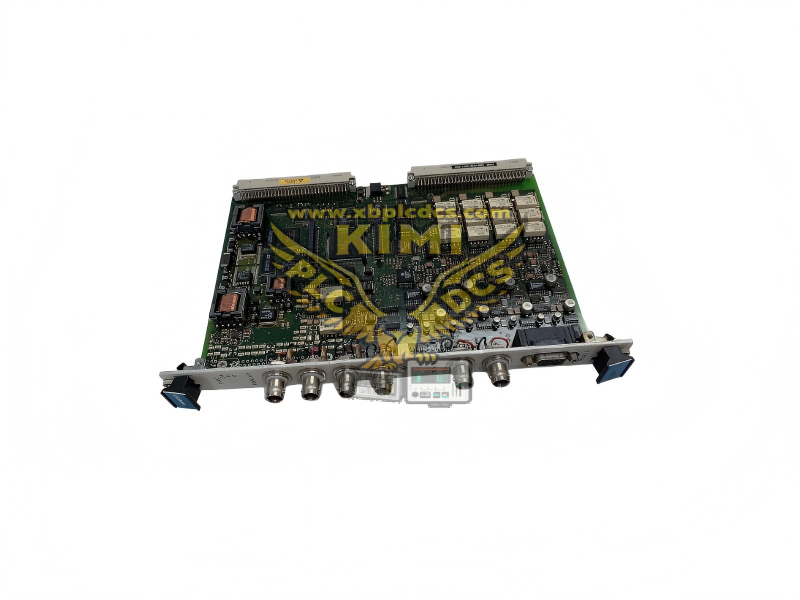

The Vibro - meter VM600 200-510-041-021 is a core MPC4 module of the VM600 machinery protection and condition monitoring system, mainly used for real - time monitoring and fault diagnosis of rotating machinery in industrial fields. It is equipped with 4 dynamic signal channels and 2 configurable auxiliary channels (for tachometer or DC input), which can collect and process parameters such as vibration, shaft displacement, and rotational speed. It supports various sensor signals (acceleration, velocity, proximity probes), has a wide frequency response range, and is compatible with VibroSight software for data analysis and alarm management. With industrial - grade wide - temperature design, high - precision measurement performance, and SIL - compliant safety functions, it is an ideal choice for machinery protection in harsh industrial environments such as power generation, oil and gas, and petrochemical industries.

• Data Logging: Built - in memory for storing historical data and alarm events

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.

3. Typical Applications