- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

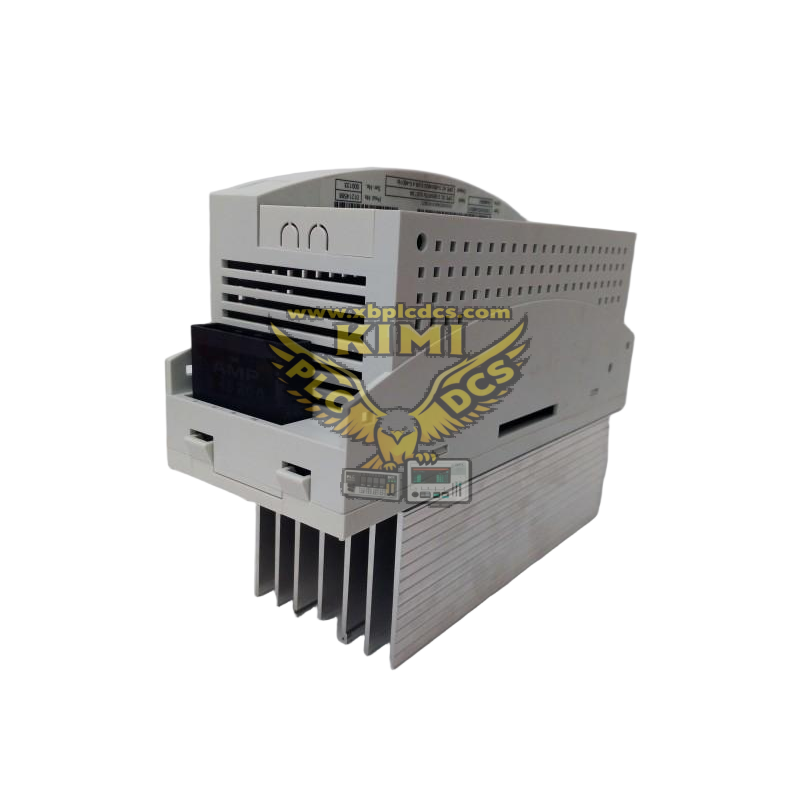

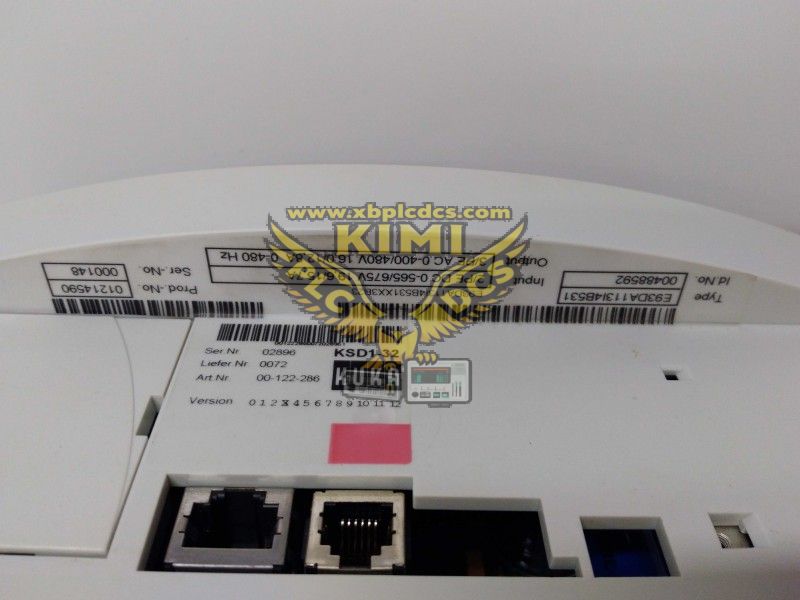

The KUKA KSD1-32 E93DA113I4B531 (Part No.: 00-122-286) is a high - power servo drive module exclusively for KUKA KR C2 robot control cabinets, mainly used to drive the servo motors of heavy - duty joints of robots (such as Axis 1 and Axis 2 of KR30 robots) to realize high - precision closed - loop control of position, speed and torque. It integrates a power drive unit and a control circuit, converts the control signal of the robot controller into the power signal required by the servo motor, and forms a closed - loop control with the motor encoder to ensure the accurate and stable operation of the robot under heavy - load working conditions. The drive is equipped with multiple protection functions such as over - current, over - voltage, over - temperature and short - circuit, and has a perfect diagnostic system, which is widely used in industrial automation fields such as automobile body welding, heavy - duty material handling and large - scale component assembly, and is a key component to ensure the high - precision and high - reliability operation of KUKA heavy - duty robots.

• Protection Class: IP20

• High Integration: Integrates Power and Control Circuits to Save Cabinet Space.

• Construction Machinery: Large - Scale Component Processing and Assembly Line Robot Operation.

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.