- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

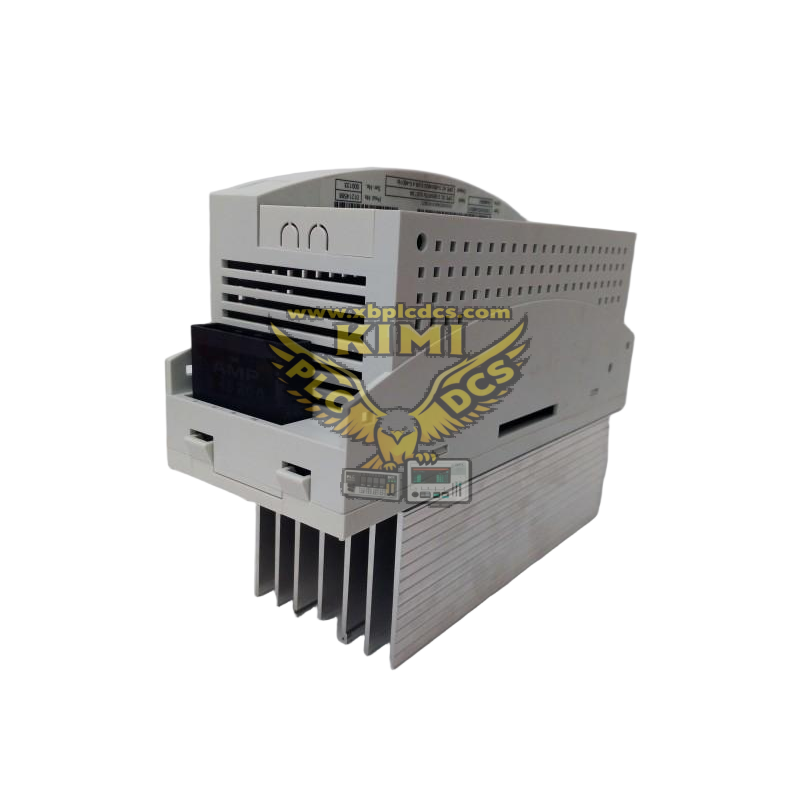

The KUKA KSD1-16 E93DA552I4B531 00-122-285 is a core servo drive module dedicated to KUKA KR C2 robot control cabinets, which is used to drive the servo motors of each joint of the robot to realize high - precision motion control of position, speed and torque. It integrates a power drive unit and a control circuit, converts the control signal of the robot controller into the power signal required by the servo motor, and forms a closed - loop control with the motor encoder to ensure the accurate and stable operation of the robot. The drive has multiple protection functions such as over - current, over - voltage, over - temperature and short - circuit, and is equipped with a perfect diagnostic system to help quickly locate faults. It is widely used in industrial automation fields such as automobile manufacturing, electronic product precision assembly, and logistics handling, and is the key component to ensure the high - precision and high - reliability operation of KUKA robots.

• Weight: 2.0 kg (4.4 lbs)

• Energy - saving Operation: Optimizes Power Output According to Motor Load to Reduce Energy Consumption.

• Aerospace: Precision Processing and Assembly of Aircraft Components.

• Safety Guidelines: Cut Off the Power Supply Before Maintenance; Follow the ESD Protection Specifications.

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.