- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

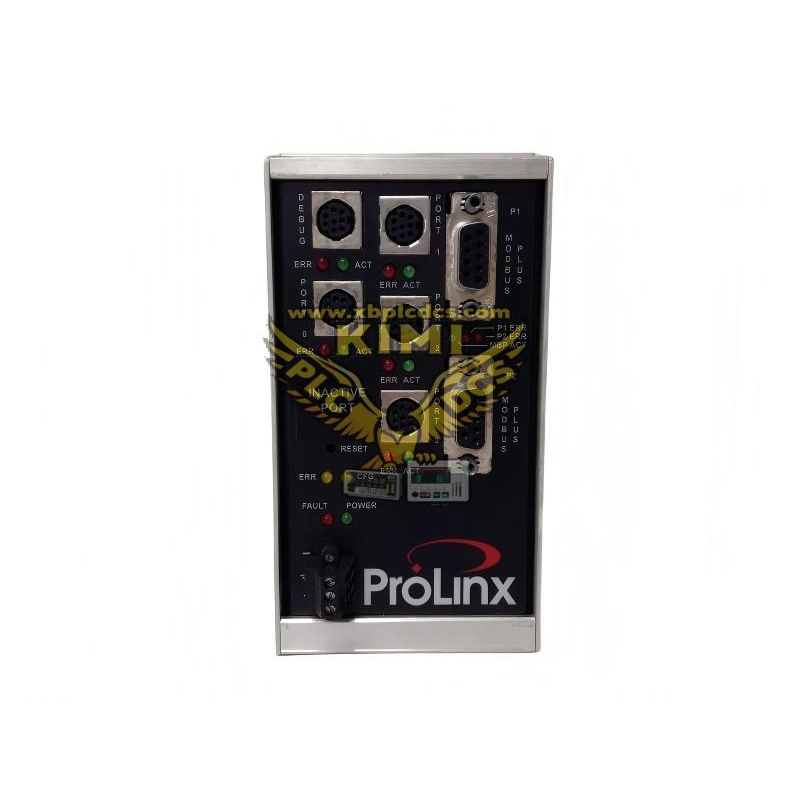

- Part number:ProSoft 5302‑MBP‑MCM4

- Product Origin:America

- HS CODE:8443919090

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

ProSoft 5302‑MBP‑MCM4 Modbus Plus to Modbus Master/Slave Gateway (4 Serial Ports)

Product Description

The ProSoft 5302‑MBP‑MCM4 is an industrial‑grade, rack‑mountable protocol gateway engineered to bridge seamless, bidirectional communication between Modbus Plus (MB+) networks and up to four independent Modbus RTU/ASCII serial devices (RS‑232/RS‑485). Purpose‑built for mission‑critical industrial automation, process control, and legacy system integration, this module features a configurable DB9 Modbus Plus port (supports Master/Slave modes) and four individually configurable serial ports (each can act as Modbus Master or Slave, with baud rates up to 115.2 kbps, parity/stop‑bit settings, and electrical isolation). It includes an internal shared database for protocol‑agnostic data mapping, built‑in diagnostics with LED status indicators, and compliance with industrial EMI/RFI standards, making it ideal for retrofitting legacy MB+ systems, integrating Modbus sensors/meters/VFDs, and reducing PLC messaging overhead in oil & gas, power generation, manufacturing, and water/wastewater applications.

Key Functions

The 5302‑MBP‑MCM4 gateway delivers robust protocol conversion and data integration with these core features: 1× DB9 Modbus Plus port (Master/Slave configurable, fully compliant with MB+ standards); 4× independent RS‑232/RS‑485 serial ports (each configurable as Modbus RTU/ASCII Master or Slave, electrically isolated for noise immunity); Internal shared database for automatic data mapping between MB+ and Modbus networks, reducing PLC MSG instruction overhead; Individually configurable serial parameters (baud rate, parity, stop bits, flow control) and MB+ network settings (node address, baud rate); Built‑in diagnostics with LED indicators (port activity, network status, fault alarms) and remote configuration via ProSoft Configuration Builder software; Hot‑swappable design for maintenance without system shutdown; Industrial‑grade EMI/RFI filtering, surge protection, and wide temperature operation (-40°C to +70°C).

Application Scenarios

The ProSoft 5302‑MBP‑MCM4 gateway is designed for high‑availability industrial applications including: Legacy Modbus Plus system retrofits to integrate modern Modbus RTU/ASCII sensors, meters, variable frequency drives (VFDs), and PLCs; Process control systems in oil & gas refineries, chemical plants, and power generation facilities requiring bidirectional data exchange between MB+ networks and distributed Modbus devices; Manufacturing automation lines connecting Modbus Plus‑based HMIs/Controllers with Modbus‑enabled robotics, machine vision systems, and production data loggers; Water/wastewater treatment plants integrating Modbus Plus SCADA systems with Modbus RTU/ASCII‑based flow meters, level sensors, and pump controllers; Retrofit projects for Allen‑Bradley PLC‑5/ControlLogix systems needing Modbus Plus to Modbus protocol conversion without replacing existing hardware.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Type | Modbus Plus to Modbus RTU/ASCII Master/Slave Gateway (4‑Port) |

| Manufacturer | ProSoft Technology |

| Model Number | 5302‑MBP‑MCM4 |

| Communication Ports | 1× DB9 Female Modbus Plus Port (Master/Slave); 4× RS‑232/RS‑485 Serial Ports (Individually Configurable, Electrically Isolated) |

| Supported Protocols | Modbus Plus (Master/Slave); Modbus RTU, Modbus ASCII (Master/Slave per Serial Port) |

| Configuration & Diagnostics | ProSoft Configuration Builder (PCB) Software; LED Status Indicators (Port Activity, Network Status, Fault Alarms); Built‑in Self‑Test (BIST) |

| Form Factor & Installation | ControlLogix‑Compatible Rack‑Mountable; Hot‑Swappable; Powered via ControlLogix Backplane (No External Power Required) |

| Operating Environment | Temperature: -40°C to +70°C; Humidity: 5–95% RH (Non‑Condensing); EMI/RFI Compliance with Industrial Standards |

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.