- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

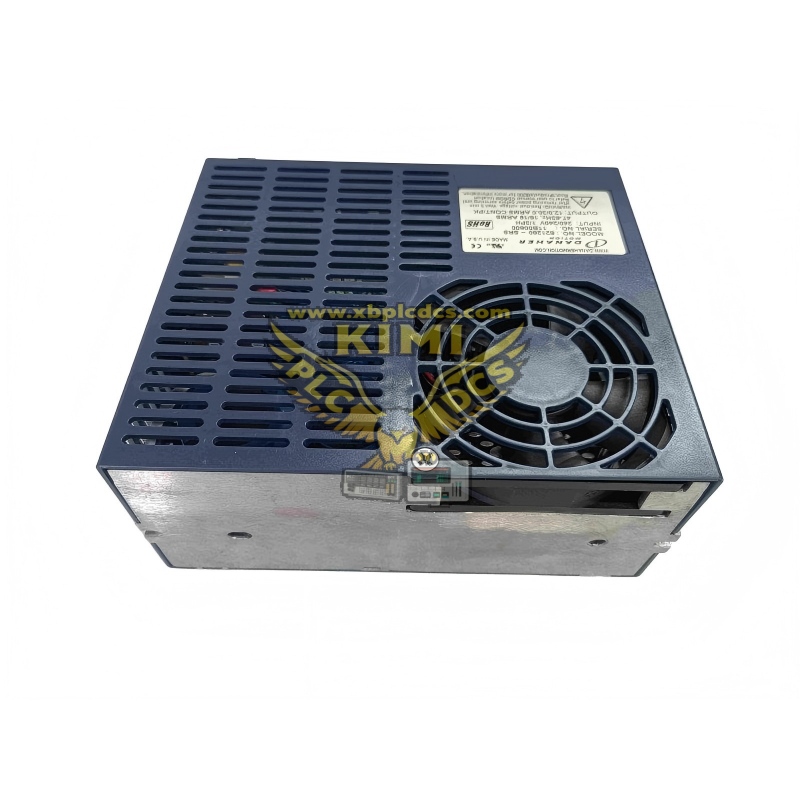

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Part number:Kollmorgen AKM42E-EKGNR-01

- Product Origin:America

- HS CODE:8708299000

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

Kollmorgen AKM42E-EKGNR-01 Servo Motor

Product Description

The Kollmorgen AKM42E-EKGNR-01 is a high-performance, brushless synchronous servo motor from Kollmorgen's AKM42 Series, engineered for precision motion control applications requiring exceptional torque density, dynamic response, and reliability. Designed with a robust permanent magnet rotor (neodymium iron boron magnets) and high-grade stator windings, this servo motor delivers smooth, low-cogging operation and consistent performance across a wide speed range—ideal for industrial automation, robotics, packaging, and material handling systems. Its compact, IP65-rated housing (with optional IP67/69K upgrades) provides protection against dust, water ingress, and harsh industrial environments, while the optimized thermal design ensures continuous operation at full load without overheating. The AKM42E-EKGNR-01 is fully compatible with Kollmorgen's ServoStar® and AKD® servo drives, enabling seamless integration and advanced motion control capabilities (position, velocity, torque mode) for high-precision automation sysems.

Key Functions

The primary function of the Kollmorgen AKM42E-EKGNR-01 servo motor is to convert electrical energy from a compatible servo drive into precise mechanical motion (rotary torque and speed) for high-accuracy industrial automation applications. It features a brushless design that eliminates mechanical wear (no commutator/brushes) and reduces maintenance requirements, with a high-torque permanent magnet rotor that delivers peak torque up to 8.5 Nm and continuous torque of 2.7 Nm at base speed (3000 RPM). The motor incorporates high-resolution feedback options (encoder/resolver) for closed-loop position control, enabling positioning accuracy down to ±0.001 degrees and rapid dynamic response (low inertia design) for high-speed, high-acceleration motion profiles. Its integrated thermal protection (PTC thermistor) prevents overheating by triggering a shutdown or warning signal when operating temperatures exceed safe limits, while the robust mechanical construction (rigid frame, precision bearings) ensures long service life (≥20,000 hours MTBF) in continuous operation. The AKM42E-EKGNR-01 supports multiple feedback interfaces (EnDat 2.2, BiSS, Hiperface, resolver) for compatibility with different control systems, and its standardized mounting/flange dimensions enable easy retrofitting and system integration. Additionally, the motor's low cogging torque (<1% of rated torque) ensures smooth motion at low speeds—critical for applications like CNC machining, robotic arms, and precision packaging equipment.

Application Scenarios

The Kollmorgen AKM42E-EKGNR-01 servo motor is widely deployed in high-precision motion control applications across industrial automation, robotics, packaging, and manufacturing sectors. In CNC machining centers (milling, turning, grinding), it drives linear axes (X/Y/Z) and rotary tables with sub-micron positioning accuracy, ensuring tight tolerances and high surface finish quality for metal and plastic components. For industrial robotics (SCARA, 6-axis articulated robots), it powers joint actuators with rapid acceleration/deceleration (up to 500 rad/s²) and precise torque control, enabling fast, repeatable pick-and-place operations in automotive assembly, electronics manufacturing, and palletizing systems. In packaging machinery (form-fill-seal, labeling, bottling lines), it controls conveyor drives, film feed rollers, and product positioning systems with smooth low-speed operation and high dynamic response, optimizing throughput and reducing product waste. The motor is also essential for material handling systems (linear actuators, gantry robots, automated guided vehicles/AGVs), where its high torque density and compact size enable efficient use of space while delivering precise load positioning. Additionally, it is used in medical equipment (diagnostic imaging systems, surgical robots) for ultra-precise motion control in sterile environments, in printing/packaging (flexo printing presses, die-cutting machines) for register control and web tension management, and in aerospace manufacturing (drilling/fastening systems) for high-accuracy component assembly.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Type | Kollmorgen AKM42 Series Brushless Servo Motor |

| Continuous Torque | 2.7 Nm (at 3000 RPM, 25°C ambient) |

| Peak Torque | 8.5 Nm (10 seconds max, 25°C ambient) |

| Base Speed | 3000 RPM (continuous); Max Speed: 6000 RPM |

| Power Rating | 0.87 kW (continuous); 2.7 kW (peak) |

| Motor Voltage | 400 V AC (3-phase); Compatible with 230 V AC (derated) |

| Feedback Type | Resolver (standard); Optional: Encoder (EnDat 2.2, BiSS, Hiperface) |

| Torque Constant (Kt) | 8.7 Nm/A (peak) |

| Inertia (Rotor) | 1.8 x 10⁻⁴ kg·m² |

| Protection Rating | IP65 (standard); IP67/69K (optional) |

| Thermal Protection | PTC Thermistor (100 kΩ at 25°C) |

| Operating Temperature | -20°C to +40°C (ambient); Max winding temp: 155°C |

| Mounting Standard | IEC 60034-7 (B5/B14 flange); NEMA 48 (optional) |

| Compatibility | Kollmorgen ServoStar, AKD, AKD2G Servo Drives |