PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Part number:S-123H 3BHB030479R0512

- Product Origin:Sweden

- HS CODE:8537109021

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

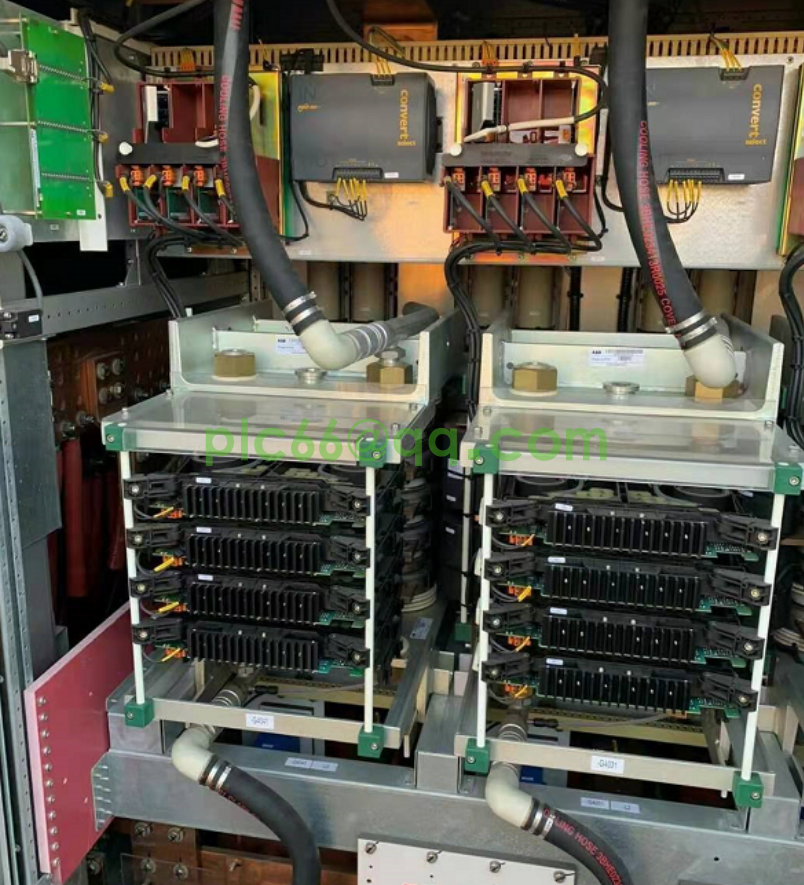

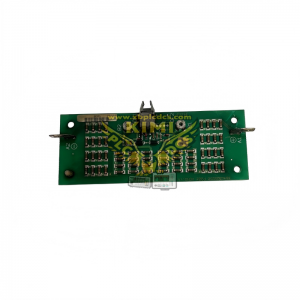

ABB ACS6000 Phase Control Module

Model: S-123H | Part Number: 3BHB030479R0512

Product Overview

The ABB S-123H/3BHB030479R0512 is a phase control module specifically designed for MVAC (Motor Voltage AC) drives. It is part of ABB's comprehensive range of drive spare parts and consumables, enabling easy replacement or upgrade of drive systems for users.

ABB is renowned for providing original spare parts and exchange units for all drives in active and classic life cycles, as well as some drives in limited life cycles. This commitment to quality and supply is crucial for maintaining the efficiency and reliability of industrial automation systems.

ACS6000 Drive System Integration

This phase control module is a component of the ABB ACS6000 drive system, a voltage source inverter specifically designed for high-power induction and synchronous motors. The ACS6000 drive adopts a common DC bus design, configurable for single-motor or multi-motor solutions.

The drive system is part of ABB's broader system drive portfolio, which includes a variety of products designed to meet the needs of different industrial applications. Its modular design allows integration of standard and optional cabinet units, each dedicated to specific functions, enabling configuration based on the specific requirements of various applications.

Optional integrated cabinet units for ACS6000 drive system include: Active Rectifier Unit (ARU), Input Reactor Unit (IRU), Inverter Unit (INU), Input Filter Unit (IFU), and Line Supply Unit (LSU).

Applications & Related Parts

The ACS6000 phase control module is exclusively engineered for ABB's ACS6000 series inverters, which are part of ABB's motor drive portfolio. These inverters are suitable for a wide range of applications, including industrial automation, power generation, and transportation systems.

Related Part Recommendation: S-073N 3BHB009884R0021 ACS6000

Document Status: Intermediate | For Internal Reference Only | Classification: Technical Component Documentation

YMGK Purchase Information

Browse the YMGK website to address issues that customers are more concerned about, including purchasing details. YMGK offers one-stop global industrial product procurement.

Contact Information

- Sales Manager: KI MI

- WeChat: 18059884790

- WHATSAPP: +86 18059884790 (Click to add)

- Email: plc66@qq.com

Core Advantages

- 121 shared inventories worldwide, with direct procurement from overseas warehouses.

- Provide favorable prices and professional after-sales warranty services.

- All products are brand new and original; spare parts come with a one-year warranty and have been tested and certified.

- For orders of more than one product, contact us to get an exclusive discount.

- If other suppliers offer lower prices for the same products, we are willing to provide further discounts based on your budget.

Customer Distribution

Our customers are from: United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

Note

All product names, trademarks, brands, and logos used on this website are the property of their respective owners. The description, explanation, or sale of products bearing these names, trademarks, brands, and logos is for identification purposes only and does not imply any affiliation with or authorization from any rights holder.

Feel free to contact us at any time for other questions!