- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

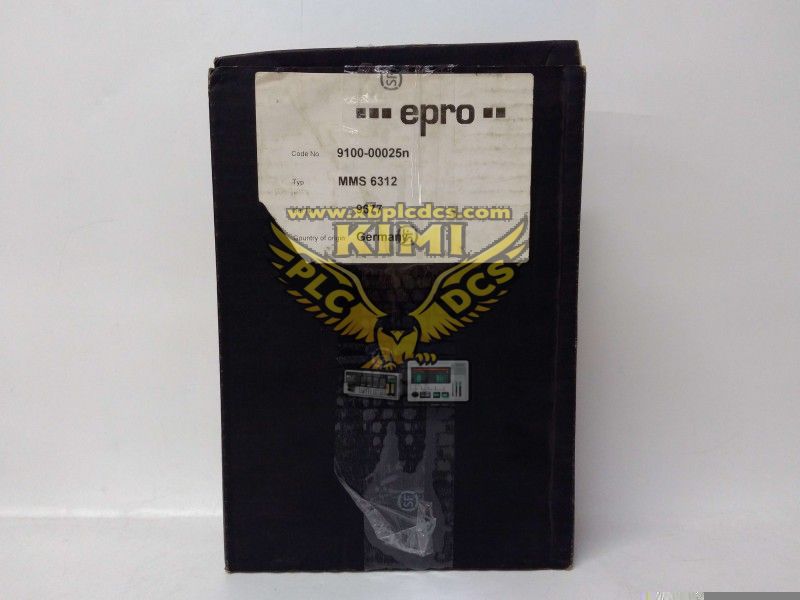

- Part number:EMERSON MMS6312

- Product Origin:America

- HS CODE:8479909090

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

EMERSON MMS6312 Machinery Protection System Module

The EMERSON MMS6312 is a high-performance multi-channel machinery protection module, belonging to Emerson's proven MMS6000 series protection systems, engineered for real-time condition monitoring and fault detection of critical rotating assets such as gas turbines, steam turbines, generators, compressors, and large motors. This module specializes in precise measurement of key mechanical parameters including radial vibration, axial displacement, differential expansion, and bearing temperature, with advanced signal processing capabilities to identify early-stage faults like imbalance, misalignment, shaft rub, and bearing degradation. Featuring configurable alarm and trip thresholds, the MMS6312 enables predictive maintenance strategies that minimize unplanned downtime and extend equipment service life. It supports seamless integration with plant DCS, SCADA, and asset management systems via standard industrial communication protocols, providing centralized visibility of machinery health status. With its ruggedized industrial design, wide operating temperature tolerance, and robust EMI shielding, the module delivers stable and reliable performance in harsh industrial environments characterized by high vibration, temperature fluctuations, and electrical interference. The MMS6312 also supports hot-swappable installation and redundant system configurations, ensuring maximum availability for mission-critical industrial processes.

| Specification Item | Details |

|---|---|

| Product Model | EMERSON MMS6312 |

| Product Type | Multi-channel Machinery Protection Module (MMS6000 Series) |

| Monitored Parameters | Radial Vibration, Axial Displacement, Differential Expansion, Bearing Temperature |

| Input Channels | 8 x Vibration Inputs; 4 x Displacement Inputs; 4 x RTD Temperature Inputs |

| Signal Processing Functions | FFT Spectrum Analysis, Peak-to-Peak Measurement, RMS Calculation, Trend Tracking, Fault Diagnosis |

| Communication Interfaces | Ethernet (TCP/IP), Modbus RTU/TCP, PROFIBUS DP, OPC UA |

| Alarm & Trip Features | Configurable High/Low Alarms, Latching/Non-latching Trips, Time Delay Settings, Event Logging |

| Redundancy Support | Module Redundancy, Power Redundancy, Communication Redundancy (Hot Standby) |

| Mounting Type | 19-inch Rack Mount; DIN Rail Mount |

| Operating Temperature | -25°C ~ +70°C (-13°F ~ +158°F) |

| Application Scenarios | Turbine Protection, Generator Monitoring, Compressor Condition Monitoring, Petrochemical & Power Generation Facilities |

Important Note: The EMERSON MMS6312 machinery protection module must be calibrated and configured by certified personnel to match the specific parameters of the monitored rotating equipment. Proper installation of proximity probes, vibration sensors, and RTDs is critical for ensuring accurate measurement and reliable protection. For detailed calibration procedures, sensor compatibility lists, and troubleshooting guidelines, please refer to the official Emerson product manual or contact an authorized technical support provider.