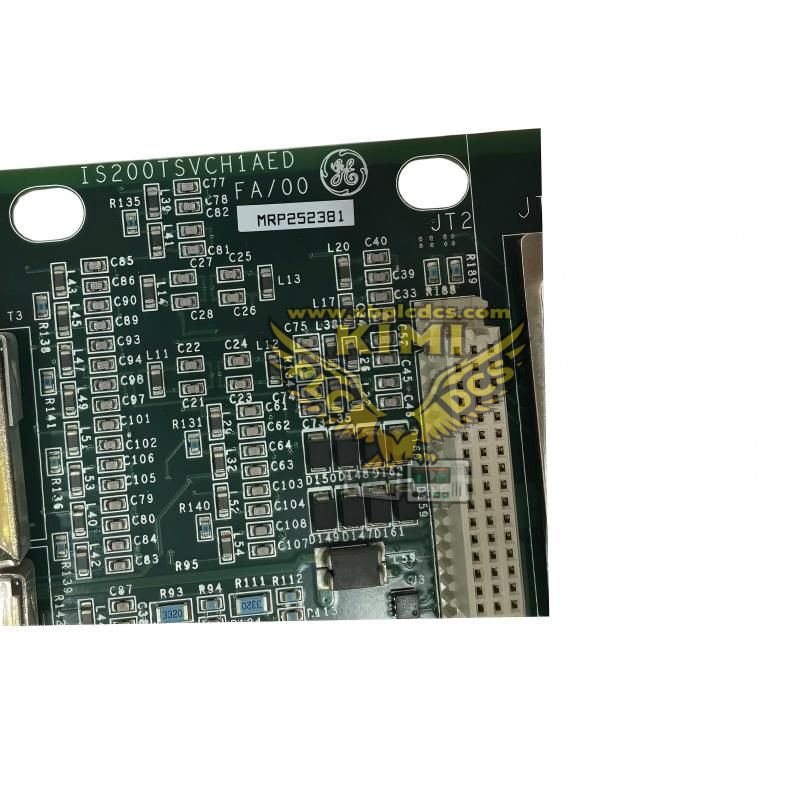

GE IS200TSVCH1AED TSVC Servo I/O Terminal Board

Servo Control & Valve Position Feedback for Mark VI/VIe Turbine Stop Valve Systems (Electro‑Hydraulic Servo Valve + LVDT Integration)

1. Core Product Overview

The GE IS200TSVCH1AED is a Turbine Stop Valve Control (TSVC) Servo I/O Terminal Board, a critical interface for Mark VI/VIe Speedtronic turbine control systems, specializing in electro‑hydraulic servo valve actuation and LVDT‑based valve position feedback for steam/gas turbine stop valves (TSV). It enables precise steam/gas flow regulation via dual servo valve outputs, 8‑channel LVDT position sensing, and failsafe emergency shutdown logic to protect turbines during faults. The board integrates 24‑terminal I/O blocks, isolated LVDT excitation, and redundant 28V DC power inputs, ensuring reliable operation in power generation, oil & gas, and petrochemical applications with harsh industrial conditions. It is compatible with PSVO I/O packs and WSVO servo drivers, supporting simplex/dual/TMR control architectures for fault‑tolerant turbine operation.

• Core Role: Turbine stop valve (TSV) servo control; LVDT position feedback processing; electro‑hydraulic servo valve actuation; failsafe emergency shutdown; Mark VI/VIe I/O interface

• Model Info: IS200TSVCH1AED (full part number); TSVC (Turbine Stop Valve Control); Mark VI/VIe Speedtronic series; Servo I/O Terminal Board

• Key Specs: 2 dual‑coil servo outputs; 8 LVDT channels (4 excitation sources); 2 pulse rate inputs; 28V DC power (3 inputs via J28); -40°C~+70°C operating temp; DIN‑rail mounting

• Reliability: Conformal coating; IEC 61000‑4 EMC immunity; redundant power; short‑circuit/overtemp protection; UL/CE certified; 24‑month warranty

2. I/O & Servo Control Capabilities

The IS200TSVCH1AED provides dual bi‑directional servo current outputs (for 2 electro‑hydraulic servo valves) with 10–120mA coil drive capability, enabling precise valve positioning for steam/gas flow control. It supports up to 8 LVDT position sensors (4 isolated excitation sources) for real‑time valve position feedback, with 0.2% linearity and 1μs response time for accurate closed‑loop control. The board includes 2 pulse rate inputs (up to 50kHz) for gas turbine fuel flow monitoring, and 24‑terminal I/O blocks (accommodating #12 AWG wiring) for analog (4–20mA/0–10V) and digital (valve open/close commands) signal integration. It implements failsafe logic to trigger emergency shutdown on overcurrent, LVDT signal loss, or power failure, preventing turbine damage from uncontrolled valve movement.

• Servo Outputs: 2 dual‑coil channels; 10–120mA coil drive; bi‑directional current control; electro‑hydraulic servo valve actuation; valve position fine‑tuning

• Feedback Sensing: 8 LVDT channels; 4 isolated excitation sources; 0.2% linearity; 1μs response; valve position closed‑loop control; LVDT signal conditioning

• I/O Interfaces: 24‑terminal blocks (#12 AWG); 2 pulse rate inputs (50kHz); 4–20mA/0–10V analog; digital open/close commands; field device direct connection

• Failsafe Logic: Emergency shutdown (ESD) trigger; overcurrent/overtemp protection; LVDT signal loss detection; power failure redundancy; turbine safety interlock

3. Power, Communication & Integration

The IS200TSVCH1AED operates on 28V DC control power, with 3 redundant inputs via socket J28 to ensure uninterrupted operation during single power source failure. It connects to Mark VI/VIe PSVO I/O packs and WSVO servo drivers (incompatible with VSVO processors) via vertical connectors, supporting simplex, dual, or TMR (Triple Modular Redundancy) control architectures for high availability. The board features transformer‑isolated LVDT excitation to eliminate ground loops and cross‑channel interference, and conformal coating for protection against dust, moisture, and chemical contaminants (IP20 rating). It integrates with Mark VIe RIM (Rack Interface Module) and I/O chassis via internal terminations, simplifying cabinet wiring and reducing installation time. Communication is via the Mark VI/VIe backplane, supporting real‑time data exchange for valve position monitoring, fault diagnostics, and remote troubleshooting.

• Power Supply: 28V DC (3 inputs J28); redundant power design; 7.5W typical consumption; surge/overvoltage protection; stable control power for servo/feedback circuits

• System Compatibility: Mark VI/VIe Speedtronic; PSVO I/O packs; WSVO servo drivers; simplex/dual/TMR control; RIM chassis integration; turbine control backplane

• Isolation & Protection: Transformer‑isolated LVDT excitation; ground loop prevention; conformal coating; IP20 rating; -40°C~+70°C temperature range; IEC 60068 vibration/shock resistance

• Diagnostics: Real‑time current/position monitoring; fault code reporting; LED status indicators; backplane data logging; remote troubleshooting via Mark VIe HMI

4. Safety Compliance & Industrial Applications

The IS200TSVCH1AED complies with UL 913 and IEC 60079‑11 for Class I, Div 2 and ATEX Zone 2 hazardous locations, limiting energy to safe levels in explosive atmospheres. It meets IEC 61800‑5‑1 for adjustable speed drive safety and IEC 61010‑1 for electrical safety, ensuring reliable operation in oil & gas, petrochemical, and power generation environments. The board’s conformal coating and enclosed design protect against dust, moisture, and chemical corrosion, while thermal shutdown prevents overheating during overloads. It is certified CE, UL, and RoHS, adhering to global industrial safety and environmental regulations. Typical applications include steam/gas turbine stop valve control, combined cycle power plants, gas compressors, and critical rotating equipment requiring precise valve actuation and failsafe protection.

• Hazardous Area Ratings: Class I, Div 2 (Groups A‑D); ATEX Zone 2; UL 913/IEC 60079‑11; explosive atmosphere safety; low‑energy design

• Safety Certifications: CE; UL; RoHS; IEC 61800‑5‑1; IEC 61010‑1; global industrial compliance for turbine control

• Environmental Resilience: -40°C~+70°C operation; 5–95% non‑condensing humidity; IEC 60068 vibration/shock; dust/moisture resistance; long‑term outdoor cabinet durability

• Industrial Sectors: Power generation (steam/gas turbines); oil & gas (upstream/midstream); petrochemical; chemical processing; critical infrastructure; turbine OEMs

5. Installation & Quality Assurance

Installation Notes: DIN‑rail/panel mount; J28 28V DC power connection; LVDT wiring per GE guidelines; I/O terminal block torque (8–10 N·m); backplane alignment with Mark VIe chassis; external trip plugs (JD1/JD2) for protection modules.

Configuration: Compatible with Mark VIe ToolboxST for servo tuning, LVDT calibration, and failsafe logic programming; supports valve position limit setting and feedback gain adjustment.

Maintenance: Hot‑swap compatible (with Mark VIe redundancy); visual LED fault indicators; LVDT signal integrity checks; conformal coating inspection; 6‑month preventive maintenance schedule.

Quality & Warranty: GE genuine module; factory‑calibrated; 24‑month standard warranty; technical support for TSVC setup, LVDT integration, and Mark VIe turbine control system commissioning.

YMGK Purchase Information

This section covers key details customers care about regarding purchasing, to support your global industrial product procurement needs.

One-Stop Global Industrial Product Procurement

Sales Manager: KI MI

WeChat: 18059884790

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.

For additional inquiries, reach out to us at any time.

All product names, trademarks, brands, and logos on this site belong to their respective owners. Their use here is for identification only, and does not imply affiliation with or authorization from the rights holders

Technical Documentation | GE IS200TSVCH1AED | TSVC Servo I/O Terminal Board for Mark VI/VIe Turbine Control