ALSTOM N895314513L (SUP-AL) Control & Data Acquisition Module

Real‑Time Signal Processing & High‑Speed I/O for Rail, Energy & Industrial Automation

1. Core Module Overview

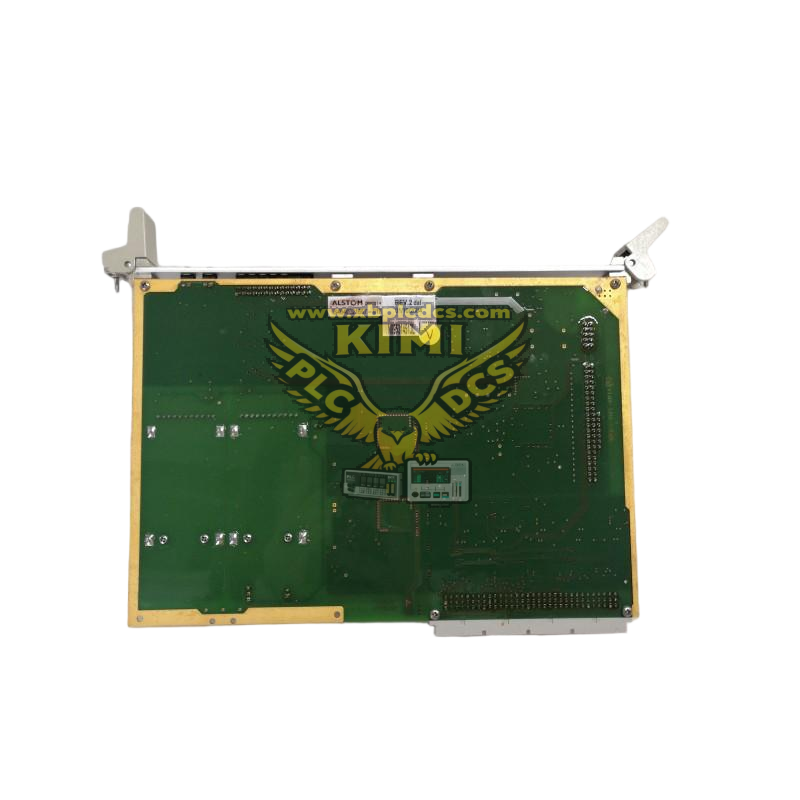

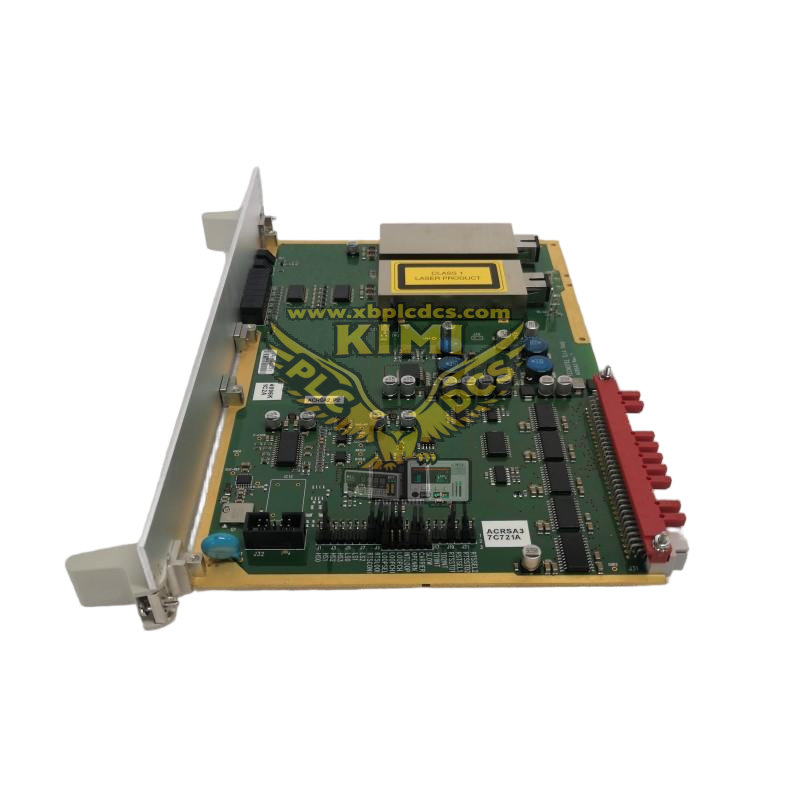

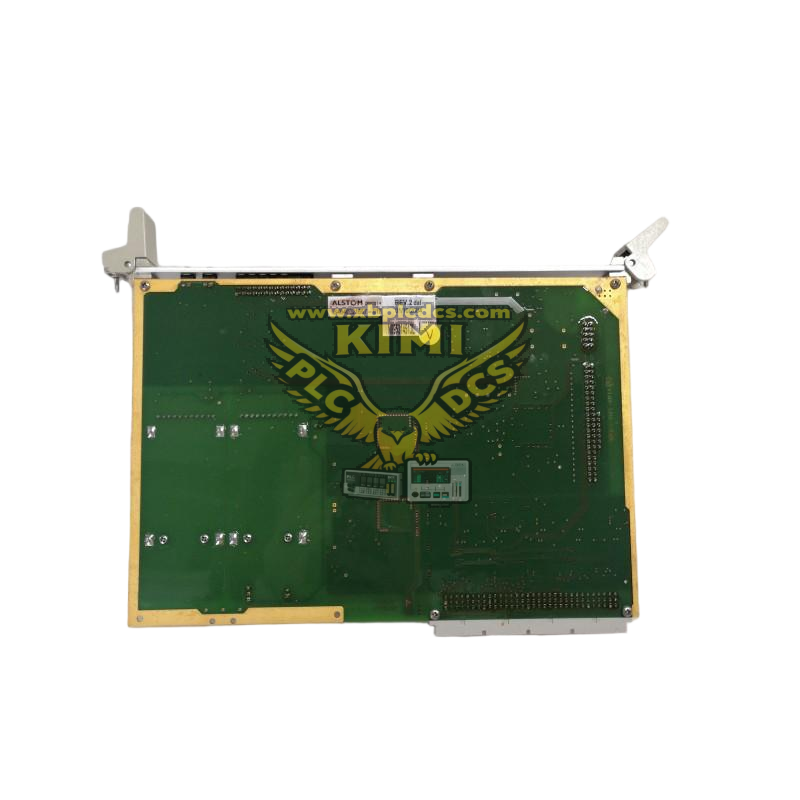

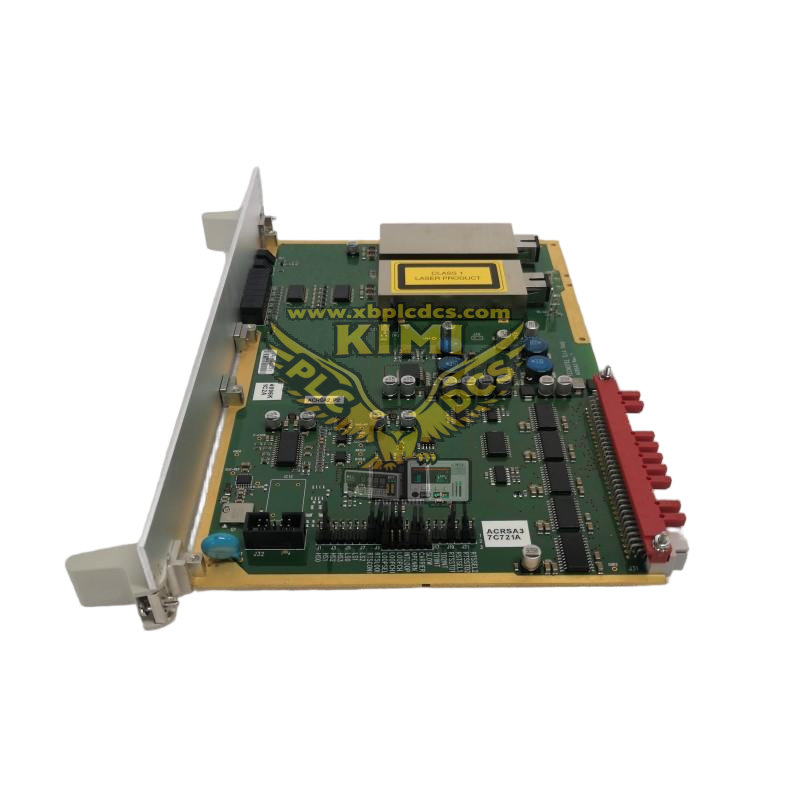

The ALSTOM N895314513L is a SUP‑AL Series high‑performance control & data acquisition module optimized for precision I/O control, real‑time signal processing, and seamless system integration in rail, power generation, and heavy industrial automation. It integrates a 24V DC redundant power supply, high‑speed processing (32‑bit ARM Cortex‑M7, 1MB logic memory), and multi‑protocol communication (Ethernet/IP, PROFINET, Modbus RTU/TCP, CANopen) to handle complex automation tasks with robust fault diagnostics. Housed in a compact IP20‑rated enclosure (105mm×160mm×55mm, 1.01kg), it operates from -40°C to +85°C with natural convection cooling, ideal for harsh environments like rolling stock, power plant DCS, and industrial process control. The module features redundant I/O paths, overcurrent/overvoltage/overtemperature protection, and non‑volatile fault logging for 24/7 reliable operation.

• Core Role: I/O control; real‑time data acquisition; signal processing; fault monitoring for rail/energy/industrial automation

• Model Info: N895314513L (base model); SUP‑AL (series); N895314513L‑X (variant)

• Key Specs: 24V DC redundant power; -40°C to +85°C temp range; 1.01kg; IP20 protection

• Reliability: Redundant I/O; overcurrent/overvoltage/overtemp protection; non‑volatile fault logging

2. I/O & Control Performance

The N895314513L delivers flexible I/O control with 30 digital inputs (24V DC), 28 digital outputs (2A relay/transistor), 4 analog inputs (16‑bit, 4‑20mA/0‑10V), 2 analog outputs (4‑20mA), and 2 high‑speed digital outputs (up to 50kHz) for pulse control applications. It uses a 32‑bit ARM Cortex‑M7 processor with 1MB logic memory, supporting 10ms/1k step scan times and real‑time control loops (≤1ms latency). Communication options include Ethernet/IP, PROFINET, Modbus RTU/TCP, and CANopen for seamless integration with Alstom’s OCR 1000 DCS, Traction Control Units (TCU), and third‑party PLCs. The module’s auto‑calibration of analog channels ensures ±0.1% accuracy, while active clamping protects against voltage transients common in rail and industrial environments.

• I/O Configuration: 30 DI (24V DC); 28 DO (2A); 4 AI (16‑bit, 4‑20mA/0‑10V); 2 AO (4‑20mA); 2 high‑speed DO (50kHz)

• Processing: 32‑bit ARM Cortex‑M7; 1MB logic memory; 10ms/1k step scan time; ≤1ms control loop latency

• Communication: Ethernet/IP; PROFINET; Modbus RTU/TCP; CANopen; Alstom OCR 1000 DCS compatibility

• Accuracy & Protection: ±0.1% analog calibration; active voltage clamping; redundant power input (24V DC)

3. Integration & Installation

The module features DIN rail mounting (105mm×160mm×55mm) for easy cabinet integration, with front‑panel LED indicators for power, communication, and fault status. It accepts 24V DC input power (redundant) and provides isolated 24V/5A to power external sensors/actuators. The SUP‑AL series marking indicates compatibility with Alstom’s TCU and DCS protocols, enabling plug‑and‑play integration with rolling stock traction systems, power plant auxiliaries, and industrial process control loops. LED diagnostics and non‑volatile fault logs allow quick troubleshooting, while hot‑swappable design minimizes downtime during maintenance.

• Mounting: DIN rail; 105mm×160mm×55mm; 1.01kg; IP20 enclosure

• Power: 24V DC redundant input; 24V/5A isolated output for external devices

• Compatibility: Alstom TCU/DCS (SUP‑AL); rolling stock; power plant DCS; industrial process control

• Maintenance: Front‑panel LED diagnostics; non‑volatile fault logging; hot‑swappable design

Typical Applications & Compliance

Key Sectors: Rail traction (metro/light rail/high‑speed trains); power generation (thermal/hydro/nuclear DCS); industrial process control (steel, mining, cement); marine automation.

Use Cases: Traction control units (TCU); auxiliary power regulation; DCS I/O processing; process valve actuation; fault‑tolerant automation systems.

Compliance: IEC 61373 (rail vibration/shock); IEC 61010 (safety); CE/UL/RoHS; -40°C to +85°C operation.

Warranty: Alstom genuine module; factory‑tested for thermal cycling/vibration; 12‑month standard warranty with extended rail/energy service options.

YMGK Purchase Information

This section covers key details customers care about regarding purchasing, to support your global industrial product procurement needs.

One-Stop Global Industrial Product Procurement

Sales Manager: KI MI

WeChat: 18059884790

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.

For additional inquiries, reach out to us at any time.

All product names, trademarks, brands, and logos on this site belong to their respective owners. Their use here is for identification only, and does not imply affiliation with or authorization from the rights holders

Technical Documentation | ALSTOM N895314513L (SUP‑AL) | Control & Data Acquisition Module for Rail, Energy & Industrial Automation