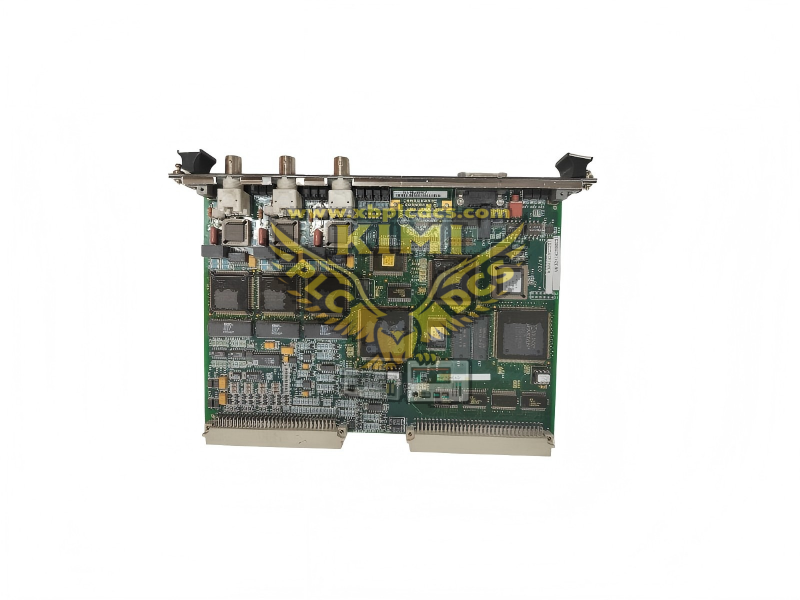

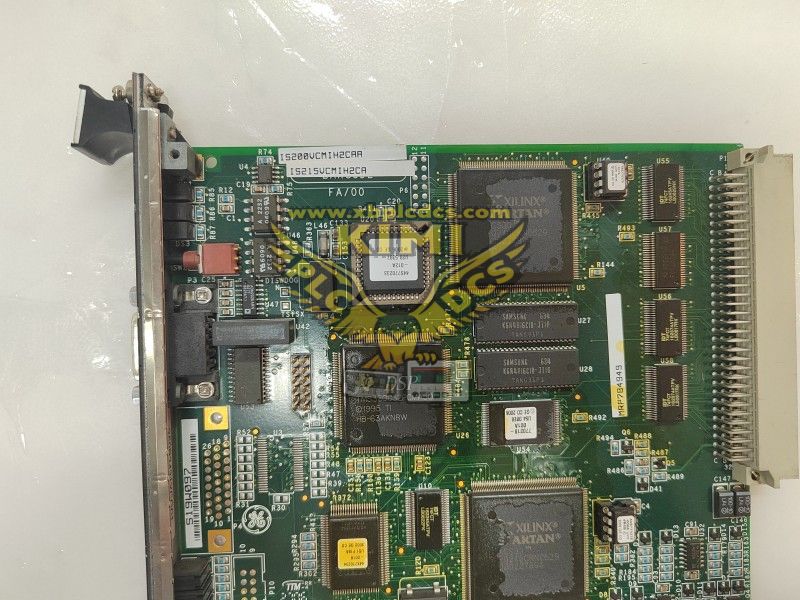

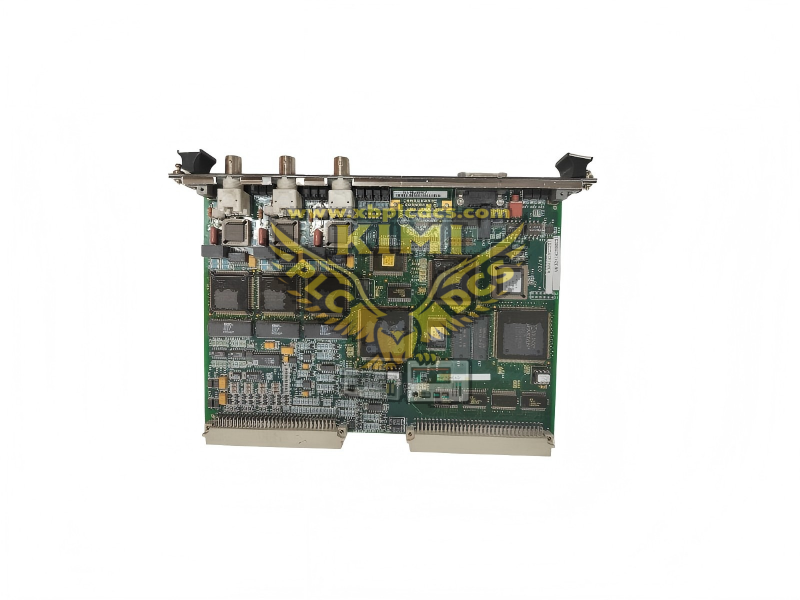

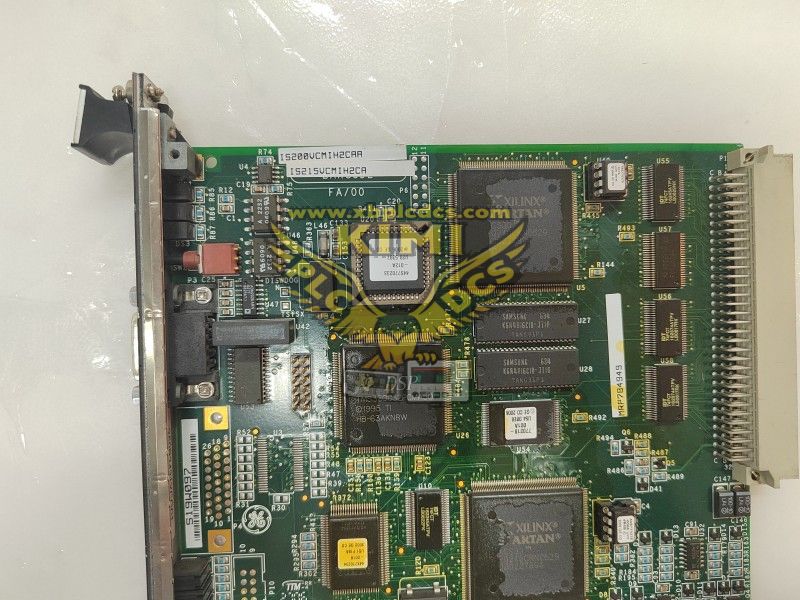

GE IS215VCMIH2CA & IS200VCMIH2CAA | VME Communication Interface Board (VCMI) for Mark VI Turbine Control

VMEbus Master Controller & IONet/ONet Communication Hub with Dual-port RAM for GE Speedtronic Mark VI & Mark V Retrofits

1. Product Overview

The GE IS215VCMIH2CA (Mark VI standard) and IS200VCMIH2CAA (Mark V upgrade) are VCMI (VME Communication Interface) boards, core communication components in GE Speedtronic Mark VI turbine control systems, also applicable to Mark V gas turbine retrofits. As VMEbus master controllers and bus arbitrators, they bridge the VMEbus backplane, IONet/ONet field networks, and system controllers, enabling multi-processor parallel operation via 256 KB dual-port RAM for VMEbus, realizing seamless data sharing between CPUs and I/O modules. The front panel is equipped with 3 ONet (IONet) ports (10 Mbps, fiber-optic/electrical) and 1 RS-232 serial port (for configuration/debugging), supporting redundant network topology, with an ONet communication distance of up to 1 km (electrical) and 20 km (single-mode fiber). It has a 32-bit VMEbus interface (64 MB address space), a 25 MHz clock, 512 KB Flash memory, and 2 MB DRAM, with 8-channel digital status I/O for system monitoring. With a redundant dual-power supply of +5 V DC (3 A) and ±12 V DC (0.8 A), reverse connection protection, 4000 V ESD protection, and an operating temperature range of -40°C to +70°C, it is suitable for critical control scenarios in power generation, oil & gas, and petrochemical industries, ensuring reliable operation of turbine speed regulation, load distribution, and safety protection systems.

Key Specifications

• Model: IS215VCMIH2CA (Mark VI Standard) | IS200VCMIH2CAA (Mark V Upgrade) | GE VCMI VME Communication Interface Board

• Compatibility: GE Mark VI turbine control system; Mark V gas turbine retrofits

• VMEbus Interface: 32-bit VMEbus master/arbitrator; 64 MB address space; 25 MHz clock; 256 KB dual-port RAM

• Communication Ports: 3×ONet (IONet) ports (10 Mbps, fiber/electrical); 1×RS-232 serial port (9.6 kbps - 115.2 kbps)

• Memory: 512 KB Flash (firmware); 2 MB DRAM (data buffer); 256 KB dual-port RAM (VME data sharing)

• I/O Monitoring: 8-channel digital status I/O (system health monitoring)

• Power Supply: +5 V DC (3 A), ±12 V DC (0.8 A each); Redundant dual-power input; Reverse connection protection

• Environmental: Operating: -40°C to +70°C; Storage: -40°C to +85°C; Humidity: 5–95% (non-condensing)

• Certifications: IEC 61010-1 safety; EMC (EN 55022/EN 55024); VMEbus compliance

2. Core Features

• VMEbus Master Control: 32-bit VMEbus arbitration and 64 MB address mapping for multi-processor system coordination

• Dual-port RAM Data Sharing: 256 KB dual-port RAM enables zero-latency data exchange between VMEbus CPUs and I/O modules

• IONet/ONet Redundancy: 3 ONet ports support redundant ring/dual-network topologies for fault-tolerant field communication

• Serial Configuration Port: RS-232 for on-site debugging, firmware updates, and system parameterization

• Mark V/VI Compatibility: IS200VCMIH2CAA for Mark V upgrades; IS215VCMIH2CA for Mark VI standard deployments

• Industrial-Grade Protection: 4000 V ESD protection, reverse power connection protection, wide temperature range for harsh turbine environments

• Status Monitoring: 8 digital I/O channels for real-time tracking of module health, port activity, and bus status

• High-Speed Data Transfer: 25 MHz VMEbus clock and 10 Mbps ONet ports ensure fast response for turbine control loops

YMGK Purchase Information

This section covers key details customers care about regarding purchasing, to support your global industrial product procurement needs.

One-Stop Global Industrial Product Procurement

Sales Manager: KI MI

WeChat: 18059884790

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.

For additional inquiries, reach out to us at any time.

All product names, trademarks, brands, and logos on this site belong to their respective owners. Their use here is for identification only, and does not imply affiliation with or authorization from the rights holders.

3. Typical Applications

• Power Generation: Gas/steam turbine control (Mark VI); Mark V turbine upgrade retrofits; generator load management systems

• Oil & Gas: Pipeline compressor turbine control; LNG plant gas turbine monitoring; offshore platform power generation control

• Petrochemical: Refinery cogeneration turbine control; chemical plant steam turbine speed regulation; fertilizer plant power system integration

• Industrial Power: Combined cycle power plant turbine coordination; waste-to-energy plant turbine control; distributed power generation systems

• Marine: Shipboard gas turbine propulsion control; LNG carrier power system monitoring; offshore rig turbine management

4. Installation & Maintenance

Installation: Insert into Mark VI VME chassis Slot (VCMI designated); connect 3 ONet ports to IONet ring/dual network; link RS-232 to configuration PC; wire redundant +5 V/±12 V power; set VME address via DIP switches; power on and verify bus arbitration & ONet communication.

Maintenance: Weekly: Check status LEDs (Power, VME Bus, ONet 1-3, Fault); Monthly: Verify VME data transfer and ONet port signal quality; Annual: Test dual-port RAM integrity and firmware update; clean module contacts and inspect power/reverse protection.

Safety Notes: Power off chassis before insertion/removal; use shielded cables for ONet/RS-232; ensure proper grounding for EMC compliance; avoid hot-swapping to prevent VMEbus damage.

Technical Document | GE IS215VCMIH2CA & IS200VCMIH2CAA | VME Communication Interface Board for Turbine Control Systems