Product

Product

- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

Nidec Control Techniques Mini MAESTRO 60X7/14 (60X714) DC Drive--KIMI

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

Product Description

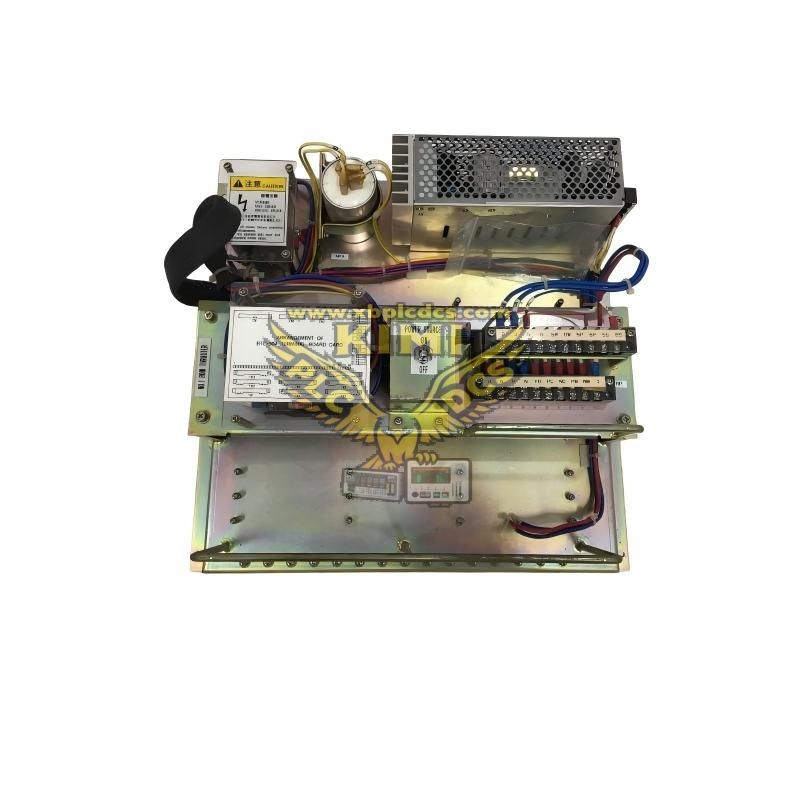

Nidec Control Techniques Mini MAESTRO 60X7/14 (60X714) DC Drive

60V 7/14A Compact DC Motor Drive for Precision Industrial Control

1. Product Overview

The Nidec Control Techniques Mini MAESTRO 60X7/14 (abbreviated as 60X714, part number DCD60X7/14) is a compact 60V DC drive designed for precise speed, torque, and position control of DC motors in industrial automation, robotics, packaging machinery, and medical equipment. It offers dual current ratings (7A continuous / 14A peak) to match diverse load demands, integrates PWM control technology for smooth motor operation, and features comprehensive protection functions (overcurrent, overvoltage, overheating, short - circuit) to ensure system safety. Its small form factor makes it ideal for space - constrained installations, while flexible configuration via software enables adaptation to various motor and load requirements, supporting high - performance and reliable operation in harsh industrial environments.

2. Key Technical Specifications

• Brand & Model: Nidec Control Techniques Mini MAESTRO 60X7/14 (60X714, DCD60X7/14)

• Product Type: Compact DC Motor Drive

• Input Voltage: 18-60VDC (Unregulated), 85-265VAC (With External Power Supply)

• Output Voltage: 0-60VDC (PWM Regulated)

• Output Current: 7A Continuous, 14A Peak (30 Seconds)

• Control Mode: Speed Control, Torque Control, Position Control (With External Encoder)

• Control Technology: PWM Control (Switching Frequency: 20kHz)

• Communication Interface: RS485 (Modbus RTU), Optional CANopen

• Feedback: Encoder Input (5V TTL/HTL), Potentiometer Input (0-10V)

• I/O Ports: 2 Analog Inputs (0-10V/4-20mA), 2 Digital Inputs, 1 Relay Output (Form A)

• Protection Functions: Overcurrent, Overvoltage, Overheating, Short - Circuit, Undervoltage

• Operating Temperature: -20°C to +70°C (-4°F to +158°F)

• Storage Temperature: -40°C to +85°C (-40°F to +185°F)

• Relative Humidity: 5% - 95% (Non - Condensing)

• Dimensions (W×H×D): 75mm × 100mm × 30mm

• Weight: Approx. 180g

• Certification: CE, UL, RoHS

3. Core Features

• Dual Current Ratings: 7A continuous / 14A peak to handle variable load conditions and short - term overloads.

• Multi - Mode Control: Supports speed, torque, and position control for diverse application requirements.

• PWM Precision: 20kHz switching frequency ensures low motor noise and smooth operation.

• Compact Design: Small footprint fits into space - limited control cabinets or equipment.

• Flexible Communication: RS485 (Modbus RTU) for easy integration with PLC/HMI systems; CANopen optional.

• Comprehensive Protection: Multiple safeguards prevent damage from electrical or thermal faults.

• Software Configurable: Parameters adjustable via CT Soft software for quick setup and optimization.

• Wide Input Range: 18-60VDC input accommodates unstable power supplies in industrial settings.

4. Typical Applications

• Industrial Automation: Conveyor systems, packaging machinery, material handling equipment.

• Robotics: Robot joints, gripper control, automated guided vehicle (AGV) drive systems.

• Medical Equipment: Diagnostic devices, rehabilitation equipment, laboratory automation tools.

• Printing & Labeling: Printing press motor control, label applicator speed synchronization.

• Textile Machinery: Spinning frame tension control, loom motor speed regulation.

• Laboratory & Test Benches: Precision motor control for testing and measurement setups.

5. Installation & Maintenance

Installation Steps

• Mounting: DIN rail or panel mounting; ensure ≥15mm clearance for ventilation.

• Wiring: Use shielded cables for power/feedback; separate power and signal wires to avoid interference.

• Power Connection: Connect 18-60VDC input; verify polarity before power - on.

• Configuration: Use CT Soft software to set control mode, current limits, and communication parameters.

Maintenance Tips

• Regular Inspection: Check LED indicators monthly for fault alerts; clean dust quarterly.

• Temperature Monitoring: Ensure operating temperature stays within -20°C to +70°C.

• Firmware Update: Update via CT Soft to access latest features and performance improvements.

• Fault Troubleshooting: Refer to LED status codes and user manual for quick issue resolution.

Technical Document | Nidec Control Techniques Mini MAESTRO 60X7/14 | 60V DC Drive | Industrial Motor Control

YMGK Purchase Information

This section covers key details customers care about regarding purchasing, to support your global industrial product procurement needs.

One-Stop Global Industrial Product Procurement

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.

For additional inquiries, reach out to us at any time.

All product names, trademarks, brands, and logos on this site belong to their respective owners. Their use here is for identification only, and does not imply affiliation with or authorization from the rights holders.

Related recommendations