- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

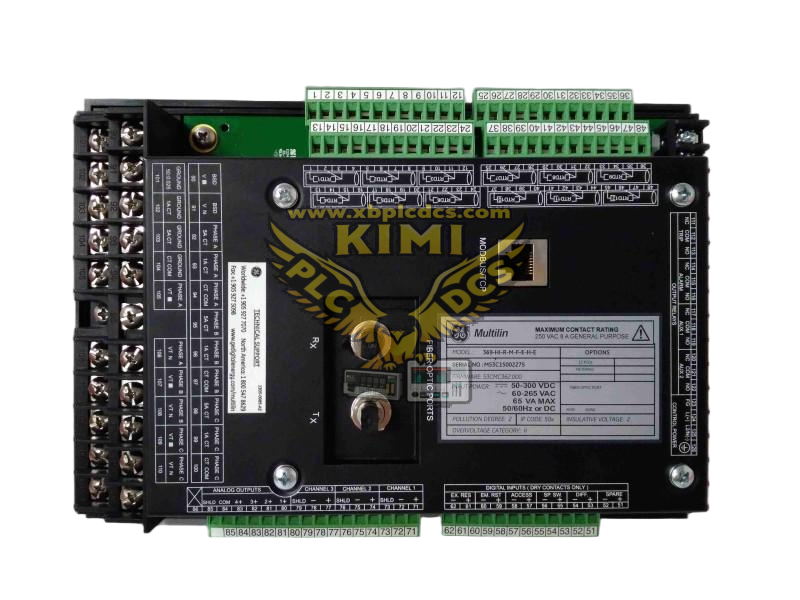

The GE Multilin 369-HI-R-M-F-E-H-E is a high - end motor management relay for comprehensive protection, monitoring, control and diagnostics of medium and high - voltage three - phase induction or synchronous motors. It integrates 12 RTD temperature monitoring, enhanced metering, fiber - optic communication, advanced diagnostics and harsh environment protection. It offers protection against overload, jam, stall, ground fault, unbalance, RTD overtemperature and other faults, with event recording, oscillography and motor health reporting functions to support predictive maintenance. It is suitable for critical motor assets in power generation, oil & gas, metallurgy and chemical industries, ensuring reliable operation and minimizing production downtime.

• Metering Package (M): Voltage, Current, Power (kW/kVA/kvar), Energy (kWh/MWh), Frequency, Power Factor, Thermal Capacity Usa

ge

• Certification: CE, UL, IEEE C37.90.1

• High - Precision Metering: Accurate Power/Energy Tracking for Energy Efficiency Optimization.

• Mining: Hoist Motors, Crusher Drives, Ventilation Fans.

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.