- main product

- ABB

- GE

- BENTLY

- TRICONEX

- HIMA

- EMERSON

- HONEYWEL

- Rockwell

- WOODWARD

- FOXBORO

- other brands

- RELIANCE(瑞恩)

- ALSTOM(阿尔斯通)

- SCHNEIDER(施耐德)

- KOLLMORGEN(科尔摩根)

- MOOG(穆格)

- Danaher(丹纳赫)

- ZYGO(翟柯)

- MOTOROLA(摩托罗拉)

- METSO(美卓)

- SMC(株式会社)

- KEYSIGHT(德科技)

- AB(艾伦 - 布拉德利)

- YASKAWA(安川)

- UNIOP(优诺普)

- PROSOFT(普罗索夫特)

- WAGO(万可)

- KUKA(库卡)

- B&R(贝加莱)

- YOKOGAWA(横河)

- REXROTH(力士乐)

- SIEMENS(西门子)

- VIBRO(维博)

- LAM(泛林)

- Hitachi(日立)

- MTL(莫泰尔)

- AMAT(应用材料)

- NI(国家仪器)

- 储能

- 其他

PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

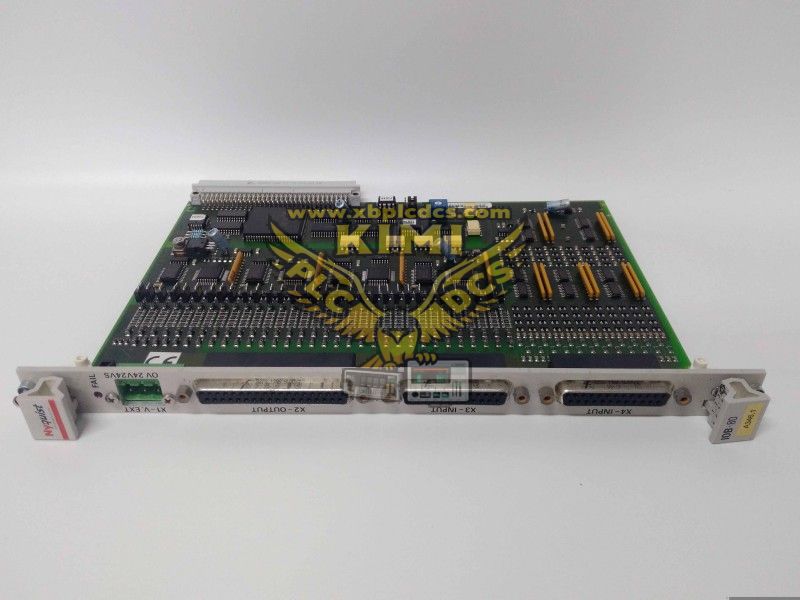

- Part number:NYQUIST IOB-80

- Product Origin:America

- HS CODE:8708299000

- Warehouse: Spot

- Warranty: 365 days

- Quality: Original module

- Condition: New

- Shipping method: Courier delivery

- Contact person: LI MING

- Contact number: +86 18059884790

- WeChat:18059884790

- E-mail: plc66@qq.com

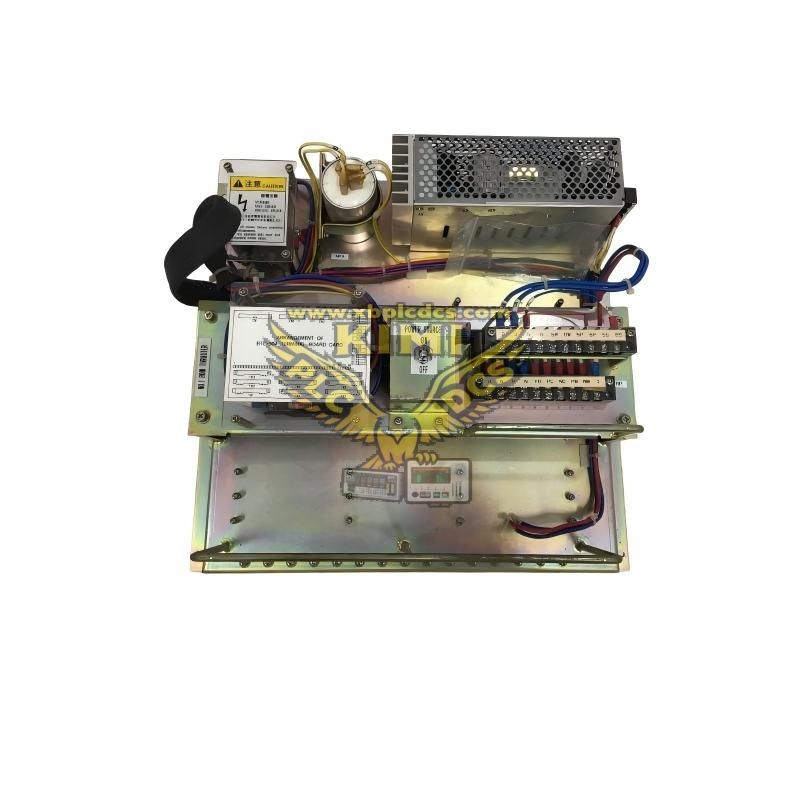

NYQUIST IOB-80 High-Density Mixed I/O Module (Also Available: Philips CNC IOB-80 I/O Board)

Product Description

The NYQUIST IOB-80 is a high-performance, channel-isolated mixed I/O module engineered for industrial automation data acquisition and control—ideal for PLC/DCS system expansion in manufacturing, process control, and test & measurement applications. This DIN-rail mount module features 32 high-precision 16-bit analog input channels (supporting RTD, thermocouple, 4-20mA, 0-10V), 32 digital I/O lines (configurable as inputs or outputs), 2 dedicated counter/timer channels, and multi-protocol communication (Modbus RTU/TCP, Ethernet IP optional) for seamless integration with industrial controllers. For CNC applications, the Philips CNC IOB-80 (PN: 40222293011) is a complementary I/O board designed for Millplus/Manualplus CNC systems, providing discrete I/O and interface capabilities for machine tool control, sensor feedback, and operator input. Both versions feature industrial-grade components, channel-to-channel galvanic isolation, overvoltage/overcurrent protection, and low power consumption for reliable operation in harsh industrial environments.

Key Functions

The NYQUIST IOB-80 mixed I/O module delivers versatile data acquisition and control capabilities with these core features: 32 isolated 16-bit analog inputs (250 kS/s max sampling rate) for temperature, pressure, flow, and level measurements; 32 configurable digital I/O lines (24 VDC, sinking/sourcing) for machine control, relay driving, and sensor input; 2 counter/timer channels (up to 1 MHz) for pulse counting, frequency measurement, and event timing; multi-protocol communication (Modbus RTU/TCP, Ethernet IP) for integration with PLCs/DCS; DIN-rail mounting for easy installation and expansion; and built-in diagnostics for fault detection and troubleshooting. The Philips CNC IOB-80 variant offers dedicated I/O for Millplus CNC systems, supporting axis control, spindle monitoring, tool changer interface, and operator panel communication—critical for precision machining applications.

Application Scenarios

The NYQUIST IOB-80 is deployed in industrial automation and process control scenarios requiring high-channel-density data acquisition and control: in manufacturing facilities, it monitors and controls production lines, robotic cells, and quality inspection systems; in oil & gas and chemical plants, it acquires process variables and controls valves, pumps, and safety systems; in power generation, it monitors equipment health and controls auxiliary systems. The Philips CNC IOB-80 is specifically used in machine tool applications, integrating with Millplus/Manualplus CNC systems to control machining operations, handle tool changes, process sensor feedback, and interface with HMI panels—ensuring precision and efficiency in metalworking and fabrication. Both modules are suitable for retrofitting legacy systems or expanding new installations, offering reliable performance in harsh industrial conditions.

Technical Specifications (NYQUIST IOB-80)

| Parameter | Specification |

|---|---|

| Product Type | High-Density Mixed I/O Module (Analog + Digital + Counter/Timer) |

| Manufacturer | NYQUIST |

| Model Number | IOB-80 |

| Analog Inputs | 32 Isolated Channels; 16-bit Resolution; Max Sampling Rate: 250 kS/s; Input Ranges: ±10V, 0-10V, 4-20mA, RTD (PT100/PT1000), Thermocouple (J/K/T/E/R/S/B) |

| Digital I/O | 32 Configurable Lines (24 VDC); Sinking/Sourcing; Max Current per Channel: 0.5 A; Overcurrent/Overvoltage Protection |

| Counter/Timer | 2 Dedicated Channels; Max Frequency: 1 MHz; Modes: Up/Down Counting, Pulse Width Measurement, Frequency Measurement |

| Communication | Ethernet (10/100 Base-T); Modbus RTU/TCP; Ethernet IP (Optional); RS485 (Optional) |

| Isolation | Channel-to-Channel: 2.5 kVrms; Channel-to-Ground: 2.5 kVrms |

| Power Requirements | 24 VDC Redundant Inputs; Typical Power Consumption: 6 W |

| Mounting & Environment | DIN-Rail Mount; Operating Temperature: -20°C to 60°C; Humidity: 5-95% RH (Non-Condensing); IEC 60068-2 Compliant |

Technical Specifications (Philips CNC IOB-80)

| Parameter | Specification |

|---|---|

| Product Type | CNC I/O Board for Millplus/Manualplus Systems |

| Manufacturer | Philips (Heidenhain Compatible) |

| Model/Part Numbers | IOB-80 / 40222293011 |

| I/O Capabilities | Discrete I/O for CNC Machine Control; Supports Axis Feedback, Tool Changer Interface, Operator Panel Inputs, and Safety Interlocks |

| Communication | Proprietary CNC Bus Interface; Compatible with Millplus/Manualplus CNC Controllers |

| Mounting & Environment | PCB Mount (CNC Controller Chassis); Operating Temperature: 0°C to 50°C; Industrial-Grade Components for Vibration/Shock Resistance |

- Global Inventory: 121 shared inventories worldwide, enabling direct procurement from overseas warehouses for faster delivery.

- Pricing & After-Sales: Competitive prices plus reliable after-sales warranty services.

- Customer Coverage: Serving clients across United States, Germany, Japan, South Korea, United Kingdom, France, Italy, Canada, Brazil, India, Australia, Russia, Spain, Netherlands, Switzerland, Sweden, Belgium, Austria, and Turkey.

- Product Quality: All items are brand new and original. Spare parts include a 1-year warranty, and all products are tested and certified.

- Discounts: Contact us for bulk-order discounts. We also offer further price adjustments if you receive lower quotes for identical products from other suppliers.