PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

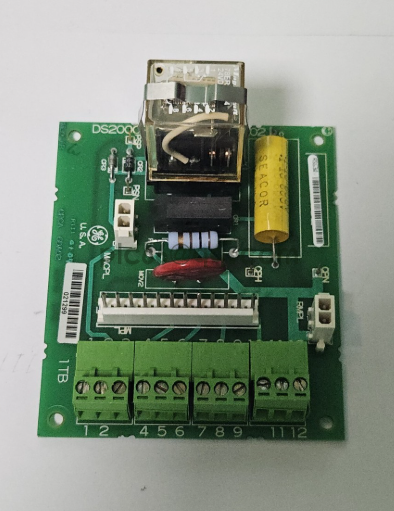

The DS200CPCAG1A Contactor Pilot Board is a specific printed circuit board (PCB) manufactured by General Electric (GE). It serves as a vital component primarily within the GE Mark V Speedtronic Turbine Control System Series and also finds applications in the EX2000 Excitation Control System.

Product Description

The DS200CPCAG1A, often referred to by its functional acronym CPCA, is a Contactor Pilot Board. Its fundamental purpose is to provide the necessary control signals and power to "pilot" or activate the coils of industrial contactors. Unlike Contactor Driver Boards (CDBA) that might regulate holding currents, the CPCA specifically functions by converting incoming AC voltage (typically 115V AC) into a DC voltage (around 105V DC) to initially close the contactor and then maintain it in the closed position.

The "A" in the part number (DS200CPCAG1A) signifies a specific functional revision, indicating it's an updated or refined version compared to the base DS200CPCAG1. This board is designed for robust operation in demanding industrial environments and includes various voltage-limiting hardware components like diodes, capacitors, and integrated circuits to ensure protection and signal integrity. It features onboard connectivity options for signals and a crucial 24VDC socket power relay.

Product Parameters

- Part Number: DS200CPCAG1A

- Manufacturer: General Electric (GE)

- Series: GE Mark V Speedtronic Turbine Control System, EX2000 Excitation Control System

- Product Type: Contactor Pilot Board

- Functional Acronym: CPCA

- Primary Function: Converts 115 V AC input into 105 V DC to drive and hold contactor coils.

- Input Voltage: 115 V AC (for conversion to drive contactors).

- Power Supply Voltage: 25 V DC (for the board's own operation and internal relay).

- Onboard Relay: Includes a 24VDC socket power relay (often rated for 15A). This relay has moving parts and requires careful handling during installation to prevent damage.

- Connectors:

- One 12-pin connector.

- Two 2-pin connectors.

- Four terminal blocks capable of connecting up to twelve signal wires (maximum of three wires per block). Careful labeling of wires during installation/removal is vital.

- Test Points:

- CPH: CPCA power positive input test point (not referenced to drive's common level, requires isolated test equipment).

- CPN: CPCA power negative input test point.

- PSP: Test point for Positive Input to CPCA Coil.

- PSN: Test point for CPCA coil control negative input.

- Board Adjustable Hardware:

- JP1: A factory test jumper. Must be in position 1-2 for normal operation. Position 2-3 enables reduced output scaling for factory testing.

- JP2: Allows coordinated operation of multiple CDBA boards (Contactor Driver Boards), implying this CPCA can integrate into such coordinated schemes, though its direct function is piloting.

- RV1: Coil current reference potentiometer. Regulates current to the contactor coil. Factory predetermined and should be carefully matched when replacing.

- PCB Coating: Normal coating for environmental protection.

- Physical Dimensions: Approximately 23.8 cm high x 8.6 cm width. Weight is about 0.45 kg.

- Operating Temperature: -35 to 65 °C.

- Country of Origin: USA.

Product Application Cases

Case 1: Digital Generator Exciter Applications (EX2000 Series)The DS200CPCAG1A is specifically used in EX2000 drive applications, where it interfaces with a digital generator exciter. It controls contactors responsible for managing the excitation current to the generator's field windings. This precise control is critical for maintaining stable generator voltage, regulating power output, and ensuring proper synchronization with the electrical grid.

Case 2: Critical Auxiliary System Control in Turbine OperationsWithin the GE Mark V Turbine Control System, this board is instrumental in piloting contactors that manage various auxiliary systems vital for turbine functionality. This includes the reliable starting and stopping of lubrication oil pumps, cooling water pumps, or fuel system components. The board ensures these high-power devices are energized and de-energized accurately during turbine startup, normal operation, and shutdown sequences.

Case 3: Safety Interlock and Protection SystemsThe DS200CPCAG1A's capability to reliably drive contactors makes it suitable for integration into turbine safety interlock and protection circuits. For example, it could control contactors that activate emergency stop mechanisms or isolate hazardous systems, ensuring that turbine operations adhere to strict safety protocols and preventing potential equipment damage or personnel injury during abnormal conditions.

Product User Reviews

"The DS200CPCAG1A is a very reliable component in our GE EX2000 excitation control system. It's built like a tank and performs its function of piloting contactors without fuss. The inclusion of test points is a definite plus for troubleshooting, though the relay needs careful handling during installation as it's a bit exposed." — Lead Electrical Technician, Power Plant

"We've been using DS200CPCAG1A boards in our Mark V turbine controls for years. They are crucial for the reliable operation of our auxiliary equipment. It's an older board, but its performance and durability speak volumes. When replacing, paying close attention to the terminal wiring and that onboard relay is key for a smooth swap." — Control Systems Engineer, Industrial Facility