PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

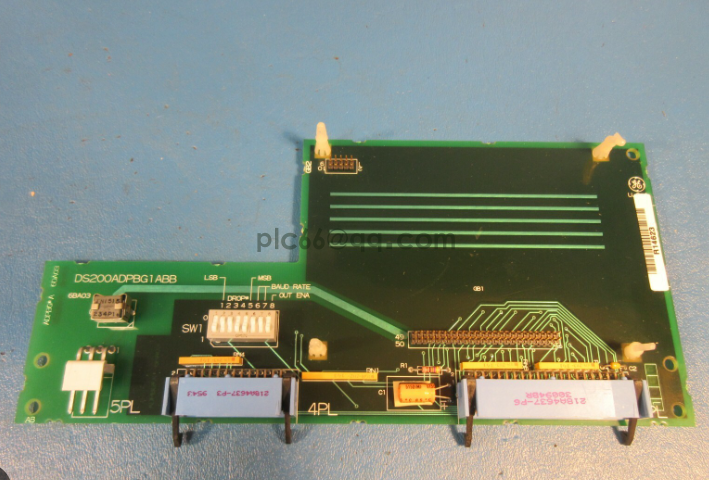

The DS200ADPBG1ABB Genius Adapter Board is a specific revision of a key component within General Electric (GE)'s Mark V Speedtronic Turbine Control Systems. Similar to the DS200ADPBG1A, its primary function is to facilitate communication between the Mark V control system and GE's Genius I/O (Input/Output) blocks.

Product Description

The DS200ADPBG1ABB is a Genius I/O Adapter Board designed to seamlessly integrate distributed Genius I/O modules into the central control architecture of the GE Mark V system.

Product Parameters

While specific detailed parameters for the "ABB" revision are largely consistent with the "A" version, here are the common characteristics of the DS200ADPB series, with specific details known for the ABB where available:

- Part Number: DS200ADPAG1ABB

- Manufacturer: General Electric (GE)

- Series: GE Mark V Speedtronic Turbine Control System (including LM versions)

- Product Type: Genius I/O Adapter Board

- Functional Acronym: ADPB

- Power Requirements: Typically +5 V dc, 6 A

- Relay Channels: 12 (This indicates its capability to handle or be associated with 12 relay channels)

- Power Supply Voltage: 28 V dc (Voltage Range: 18 - 32 VDC)

- Mounting: Designed for integration within Mark V system racks, often utilizing screw mounts or internal connectors.

- Technology: Surface mount technology, enhancing durability and compactness.

- Operating Temperature: -30 to +65 degrees Celsius

- Physical Dimensions: Approximately 15.9 cm high x 17.8 cm width (known to have a distinctive "L" shape).

- Connectors: Features one 40-pin connector and one 26-pin connector. May also have smaller 3-pin and 10-pin connectors.

- Configuration: Includes one block of 8 switches for configuring the board and manually-moveable hardware jumpers for supreme customization purposes.

- PCB Coating: Normal coating for protection.

- Status Indicators: Typically includes two diagnostic LEDs; one for hardware health and the other for LAN communication status (both should be solid green in normal operation).

- Manual: GEH-6195F (relevant manual for the Mark V system).

- Significant Product Revisions: This product makes use of its full possible range of three significant product revisions (including an A-rated and a B-rated functional revision, and a B-rated artwork revision).

Product Application Cases

The application scenarios for the DS200ADPBG1ABB are broadly the same as its "A" revision, as its core function remains consistent:

Case 1: Comprehensive Turbine Control and MonitoringIn large power generation units (gas, steam, or combined-cycle turbines), the DS200ADPBG1ABB is integral to the Mark V's ability to monitor and control a vast array of turbine parameters. This includes interfacing with Genius I/O blocks that gather data from hundreds of temperature sensors, pressure transducers, vibration probes, and speed sensors, while simultaneously sending commands to fuel valves, bypass valves, and other actuators for precise speed, load, and temperature control.

Case 2: Auxiliary Systems Integration in Industrial PlantsBeyond the core turbine, the DS200ADPBG1ABB enables the Mark V system to extend its control to various auxiliary systems within an industrial plant, such as lubrication oil systems, cooling water circuits, and fuel gas conditioning units. By connecting to distributed Genius I/O blocks in these areas, the board facilitates the monitoring of pump statuses, valve positions, fluid levels, and provides control over these critical support systems.

Case 3: Safety and Emergency Shutdown Systems (ESD)For critical safety functions and emergency shutdown (ESD) systems, the DS200ADPBG1ABB ensures that rapid and reliable communication exists between redundant Mark V controllers and field-mounted safety interlocks and final elements (e.g., trip valves). The board's role in facilitating robust I/O communication is crucial for implementing two-out-of-three voting logic in the Mark V system, enhancing overall system safety and preventing catastrophic failures.

Product User Reviews

"The DS200ADPBG1ABB is a testament to GE's engineering for longevity. We've seen these boards perform flawlessly in our Mark V systems for decades. They are the backbone of our Genius I/O connectivity, providing reliable and deterministic communication for critical turbine parameters. While they're older technology, their robustness means they continue to be highly effective." — Lead Control Systems Engineer, Power Generation Company

"When troubleshooting a Mark V system, the DS200ADPBG1ABB is rarely the culprit. They are incredibly reliable. The presence of configuration switches and jumpers on the board, though rarely adjusted after initial setup, speaks to the customizability and flexibility built into these boards for specific site requirements.