PLC/DCS module-NEWS

Featured

Contact Us

Contact: YMGK Industrial Control

Phone: +86 18059884790

E-mail: plc66@qq.com

Add: fujian xiamen

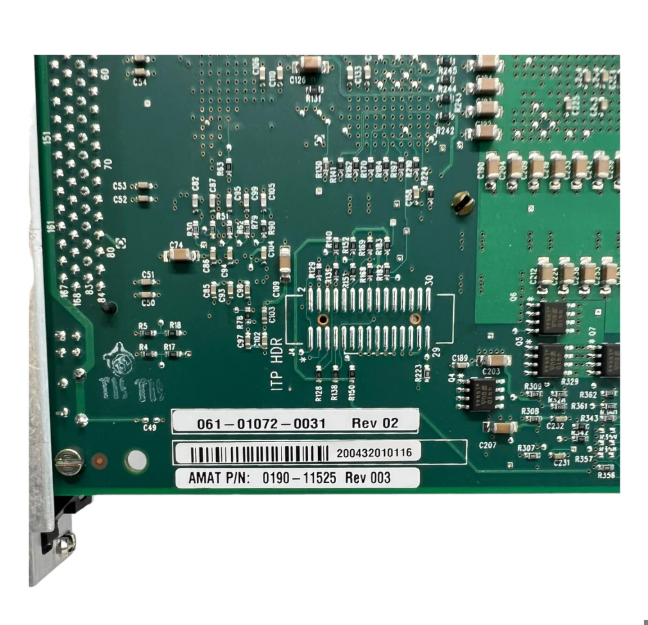

The part number 0190-11525 is associated with a specialized PC Board or Mother Board primarily used in Applied Materials (AMAT) semiconductor manufacturing equipment. It is often referred to as a "CARD PIII 400MHZ 128MB RAM VME BUS SINGL" or "MOTHER BOARD AMAT PIII".

This module is a crucial component in the control systems of highly complex semiconductor fabrication tools.

Product Description

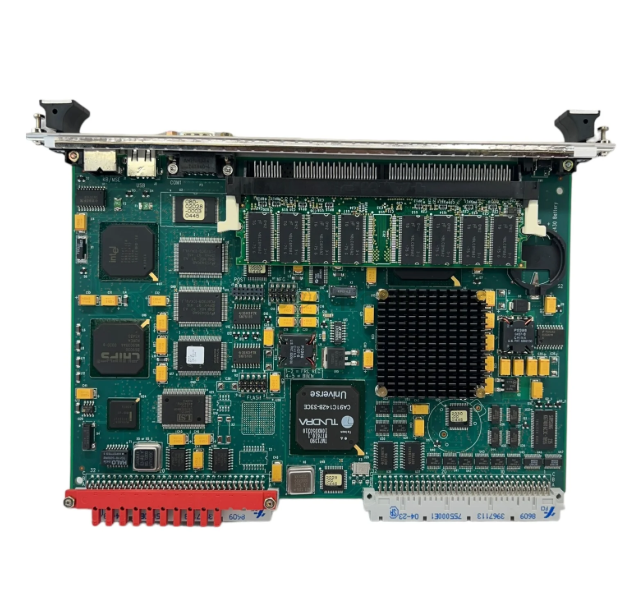

The 0190-11525 is a VMEbus-compatible single board computer (SBC), likely manufactured by Radisys for Applied Materials. It essentially serves as a dedicated computer on a board, featuring a Pentium III (PIII) processor running at 400MHz and equipped with 128MB of RAM. The VMEbus (VERSAmodule Eurocard bus) is a well-established, high-performance bus standard commonly used in industrial, military, and aerospace applications due to its robust and modular nature.

This board provides the computing power and control logic necessary for specific functions within Applied Materials' intricate semiconductor processing equipment. It handles data processing, real-time control, and communication tasks, ensuring the precise operation of the various subsystems within the larger tool. Given its age (Pentium III era), these boards are typically found in older generations of AMAT equipment.

Product Specifications (General based on common descriptions)

- Part Number: 0190-11525

- Manufacturer (for AMAT): Applied Materials (OEM by Radisys)

- Product Type: PC Board / Single Board Computer (SBC) / Mother Board

- Processor: Intel Pentium III (PIII)

- Processor Speed: 400 MHz

- RAM: 128 MB

- Bus Interface: VMEbus (VME Bus SINGL)

- Application: Integral component in Applied Materials (AMAT) semiconductor manufacturing equipment.

- Status: Often listed as "Discontinued by Manufacturer" (for Radisys, as this is an older technology), but available through surplus and repair channels.

Product Application Cases

The 0190-11525 is exclusively used within the highly specialized and demanding environment of semiconductor fabrication facilities (fabs). Specifically, it's found in various Applied Materials (AMAT) tools, which are global leaders in providing equipment for chip manufacturing.

- Wafer Processing Equipment: This board would be integrated into the control systems of AMAT's complex wafer processing machines, such as:

- PVD (Physical Vapor Deposition) Systems: Used for depositing thin films onto semiconductor wafers.

- CVD (Chemical Vapor Deposition) Systems: For depositing various material layers using chemical reactions.

- Etch Systems: For precisely removing material from the wafer surface.

- CMP (Chemical Mechanical Planarization) Systems: For planarizing wafer surfaces.

- Implant Systems: For doping wafers with specific impurities.

- Tool Control and Automation: The board provides the computational backbone for:

- Real-time process control: Executing precise control algorithms for deposition rates, temperature profiles, gas flows, and robotic wafer handling.

- Data acquisition and monitoring: Collecting sensor data from various parts of the tool to ensure process stability and quality.

- Communication: Interfacing with other sub-systems within the tool and with the factory's larger Manufacturing Execution System (MES) or Supervisory Control and Data Acquisition (SCADA) systems.

- Fault detection and diagnostics: Analyzing operational data to identify anomalies and trigger alarms or safety shutdowns.